Concealed Head Threaded Studs

Send Inquiry

Concealed head threaded studs made of stainless steel don’t just resist corrosion,they have got plenty of strength, which makes them good for structural connections. The 304 and 316 stainless steel types (those austenitic grades) usually aren’t magnetic, and that’s a big deal in setups where magnetic fields matter. Like in MRI machines, electronic casings, or certain aerospace gadgets. The fact that they’re strong and non-magnetic means these stainless steel screws work in a bunch of different technical fields.

Advantage

Concealed head threaded studs made of stainless steel are corrosion-resistant by nature, but they can go through passivation. This chemical process boosts the natural protective oxide layer, especially after they have been machined, to really up their corrosion resistance. Usually, they come in a plain "mill finish" (that smooth metallic look) or passivated. Basically, these stainless steel screws don’t need plating,they just rely on the base material’s properties to stay protected and look good.

How to install correctly

Concealed head threaded studs require a specific riveting process. The screw is inserted into pre-drilled holes in the materials being joined. Using a suitable riveting tool (e.g., orbital or radial riveter), the protruding threaded end is mechanically deformed ("riveted") against a die, forming a secondary head that permanently clamps the materials, creating a strong, flush joint.

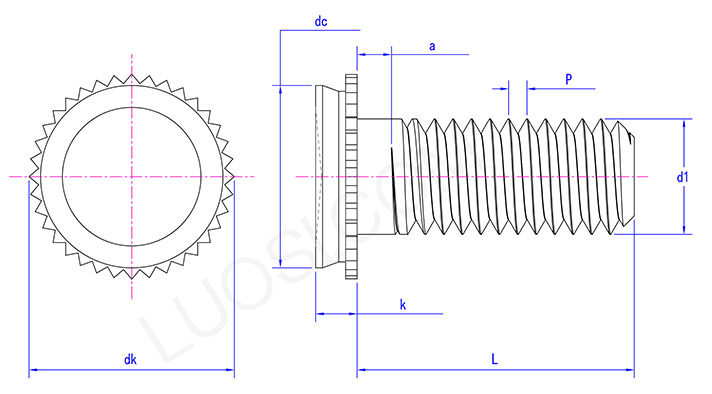

Product parameters

| Mon | M3 | M4 | M5 |

| P | 0.5 | 0.7 | 0.8 |

| k max | 1.8 | 1.8 | 1.8 |

| dc max | 4.35 | 7.35 | 7.9 |

| dk max | 5.46 | 8.58 | 9.14 |

| dk min | 4.96 | 8.08 | 8.64 |

| d1 | M3 | M4 | M5 |

| a max | 1.6 | 1.6 | 1.6 |