Aluminium Alloy Concealed Head Threaded Studs

Send Inquiry

Aluminium alloy concealed head threaded studs made of Aluminium alloy meet strict aerospace standards (like NASM, MS) and military specs (MIL-S) to make sure they’re all the same quality. They come in different sizes,diameters like 1/8 inch, 5/32 inch, 3/16 inch and different grip lengths to fit different material thicknesses. The threads are usually UNJ or MJ types, which are designed to handle high stress without breaking down over time.

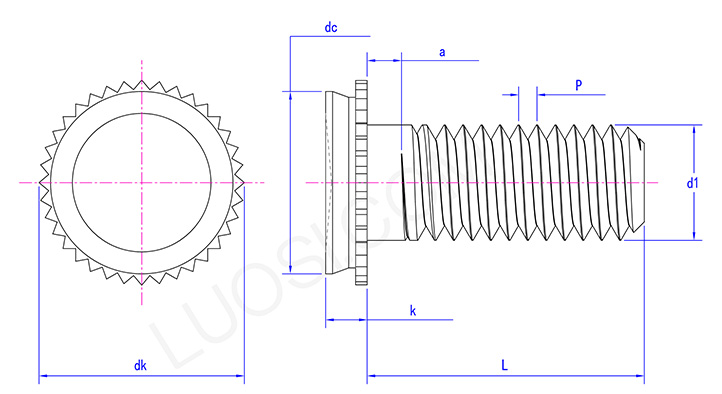

Getting the exact sizes right is important for installing them right and making sure they work, and all the precise measurements are laid out in detailed spec sheets. Basically, these standards and size options make sure they’re reliable for different applications where they need to hold up long-term.

Product parameters

| Mon | M3 | M4 | M5 |

| P | 0.5 | 0.7 | 0.8 |

| k max | 1.04 | 1.04 | 1.04 |

| dc max | 4.35 | 7.35 | 7.9 |

| dk max | 5.46 | 8.58 | 9.14 |

| dk min | 4.96 | 8.08 | 8.64 |

| d1 | M3 | M4 | M5 |

| a max | 1.6 | 1.6 | 1.6 |

Install

Installing these aluminium alloy concealed head threaded studs needs specific tools: a rivet gun and either a bucking bar or a pulling tool. You use these to squish the end of the screw shaft, which forms a second head (called the shop head) that clamps the materials tight. This cold-forming way of doing it makes a permanent joint that’s strong and won’t come loose from vibrating. The best part is the flush head stays put during installation, so the surface ends up smooth,no bumps or ridges sticking out.

Why can't standard screws be used instead?

Standard screws (like hex bolts) are not direct substitutes for aluminium alloy concealed head threaded studs. The unique design requires riveting the threaded end for permanent, vibration-resistant fastening. Substituting would compromise joint integrity and the critical flush finish. Their installation process and final clamping mechanism are fundamentally different.