Welding Studs For Short Period Arc Welding

Send Inquiry

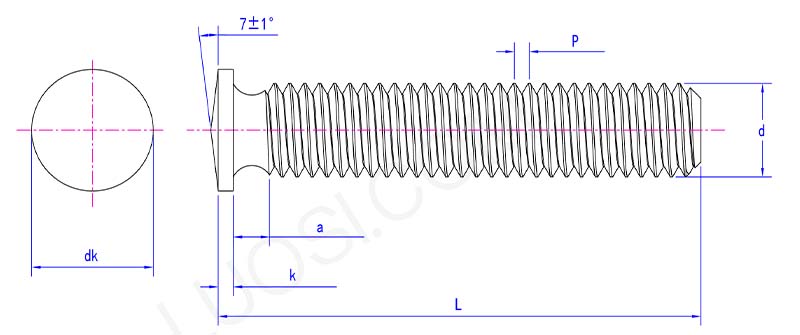

The welding studs for short period arc welding are composed of a specific material for the body and the head. The diameter of the body usually ranges from 3 millimeters to 16 millimeters in various specifications, and the length offers different options to meet different requirements.

Product parameters

|

Mon |

M3 |

M4 | M5 | M6 | M8 | M10 |

|

P |

0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 |

|

a max |

1.5 | 1.5 | 2 | 2 | 2 | 2 |

|

dk max |

4.2 | 5.2 | 6.2 | 7.2 | 9.2 | 11.2 |

|

dk min |

3.8 | 4.8 | 5.8 | 6.8 | 8.8 | 10.8 |

|

k max |

1.4 |

1.4 |

1.4 |

1.4 |

1.4 |

1.4 |

|

k min |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

Application Advantages

Welding studs for short period arc welding are used to repair the exhaust insulation plate of the truck. Using them can solve the problem of the exhaust insulation board making a rattling sound. It can be quickly installed onto the frame in just 0.3 seconds, and it won't deform even if it generates a small amount of heat. Tighten the bolt insulation plate with the locking nut. It won't loosen even when passing through uneven roads. No need to drill holes on rusty metal.

For short period arc welding, a ceramic sleeve needs to be placed around the welding studs. When pulling the trigger, the welding gun will slightly lift the studs, creating an arc, and then strike them firmly down. The sleeve can shape the molten metal and protect the weld from air erosion. It is of vital importance - do not attempt without it.

The welding studs can handle dirty metals more effectively. When welding on outdoor or slightly rusty/soiled sheets, they usually penetrate through the metal. The powerful electric arc can burn off tiny impurities. Even if it doesn't completely clean, it can still achieve a good welding result. However, to ensure reliability, cleaning is always the better option.

Product Features

One of the features of welding studs for short period arc welding is the shape and structure of the head. The protrusions or special shapes can precisely guide the arc to a specific position when a short-cycle arc is generated, causing a rapid increase in local temperature and enabling rapid welding. At the same time, it reduces the thermal impact on the surrounding areas.