Cheese Head Studs For Stud Welding

Send Inquiry

The head of the cheese head studs for stud welding is round and bulging like a piece of cheese, and below it is a threaded rod. It can handle general daily usage scenarios or low-demand industrial environments. Comply strictly with the standards of GB/T 10433-1989.

Product Advantages And Parameters

Using cheese head studs can create neat anchor points. Weld M5 screws onto the back plate - the flat heads should be flush with the metal. Use cable ties to pass through the slots on the heads or fix the cable troughs with screws. In confined spaces, it is more convenient to clean the components than hex head screws.

Mon

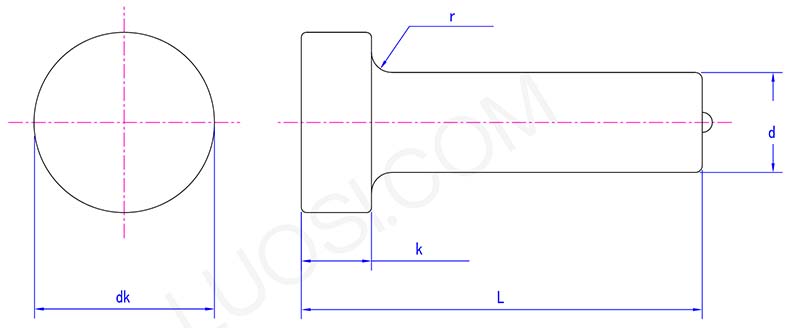

Φ6

Φ8

Φ10

Φ13

Φ16

Φ19

Φ22

d min

5.76

7.71

9.71

12.65

15.65

18.58

21.58

d max

6.24

8.29

10.29

13.35

16.35

19.42

22.42

dk max

11.35

15.35

18.35

22.42

29.42

32.5

35.5

dk min

10.65

14.65

17.65

21.58

28.58

31.5

34.5

k max

5.48

7.58

7.58

10.58

10.58

12.7

12.7

k min

5

7

7

10

10

12

13

r min

2

2

2

2

2

3

3

If you need to install plastic trim pieces inside the car door, simply use cheese head studs for stud welding and it will be a breeze. It can be easily welded to the metal plate using a stud gun - the low-profile head remains flush. The worker simply needs to place the decorative cap over the thread and install the nut. The bulky head will not catch on the wires, and the wide base will not pass through thin metal like a small stud.

Using cheese head studs offers fast welding speed and seamless joints. Its smooth low-profile design does not leave food residues. When welding M6 screws, fix the guide rail with bolts and it can be freely disinfected. It is easier to hide bacteria than exposed bolt heads and complies with FDA standards.

Product Features

The round head design of cheese head studs for stud welding can increase the contact area with the welding equipment, making the welding process more stable and preventing the electric arc from escaping. This ensures the stability of the welding quality. The welding ends are usually specially treated, allowing for quick arc initiation and uniform melting, which enables a better integration with the base material.