Weld Studs For Capacitor Discharge Welding

Send Inquiry

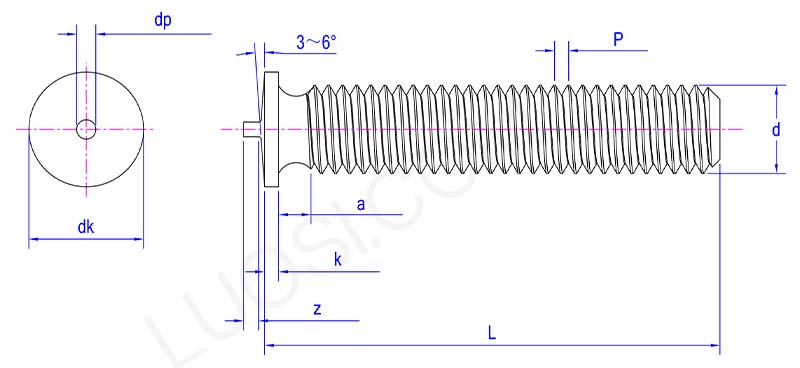

Weld studs for capacitor discharge welding are usually composed of a specific material shaft and a welding end. The shaft part has various diameters and lengths. The welding end usually has a special design, such as small protrusions or sharp tips, which can better guide the current.

Product Features

These weld studs are used to repair loose metal roof trim. They can solve the problem of the trim screws coming off from the thin roof panel. It can pass through the trim strip in just 0.1 seconds without any thermal deformation. It is fixed with washers/nuts. During a hurricane, it is even more secure than screws. It won't leak due to extra holes.

Weld studs for capacitor discharge welding can complete the welding process in just a few milliseconds. A powerful current instantly melts the tip, allowing it to connect with the thin metal, even on painted or coated surfaces. There is almost no heat diffusion, so it won't warp or burn through the precision sheet metal. It is highly suitable for decorative parts and electronic products.

Weld stud for capacitor discharge welding are portable and low-power. They use small, battery-like welding guns. No heavy transformers or three-phase power sources are required. They can be plugged into regular sockets or used with wireless devices. They are highly suitable for truck, trailer or workshop site maintenance, without the need for large welding equipment.

Product parameters

|

Mon |

M3 | M4 | M5 | M6 | M8 | M10 | M12 |

|

P |

0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

|

dk max |

4.65 | 5.65 | 6.68 | 7.68 | 9.72 | 11.72 | 14.22 |

|

dk min |

4.35 | 5.35 | 6.32 | 7.32 | 9.29 | 11.29 | 13.79 |

|

dp max |

0.78 | 0.78 | 0.88 | 0.88 | 0.88 | 1.1 | 1.1 |

|

dp min |

0.52 | 0.52 | 0.62 | 0.62 | 0.62 | 0.85 | 0.85 |

|

z max |

0.53 | 0.63 | 0.73 | 0.83 | 0.93 | 1.03 | 1.13 |

|

z min |

0.27 | 0.37 | 0.47 | 0.57 | 0.67 | 0.77 | 0.87 |

|

k max |

1.3 | 1.3 | 1.4 | 1.4 | 1.5 | 1.5 | 1.5 |

|

k min |

0.7 | 0.7 | 0.8 | 0.8 | 0.9 | 0.9 | 0.9 |

|

a max |

1.5 | 2.1 | 2.4 | 3 | 3.75 | 4.5 | 5.25 |

Advantages

The weld studs for capacitor discharge welding have a fast welding speed and causes minimal damage to the workpiece. The capacitor discharge welding process is completed in an extremely short period of time, usually taking only 1 to 3 milliseconds. It significantly reduces the thermal impact on the weldment, and is particularly suitable for welding materials that are sensitive to heat and prone to deformation, such as thin plates.