Uniformly Coated Galvanized Steel Wire

Send Inquiry

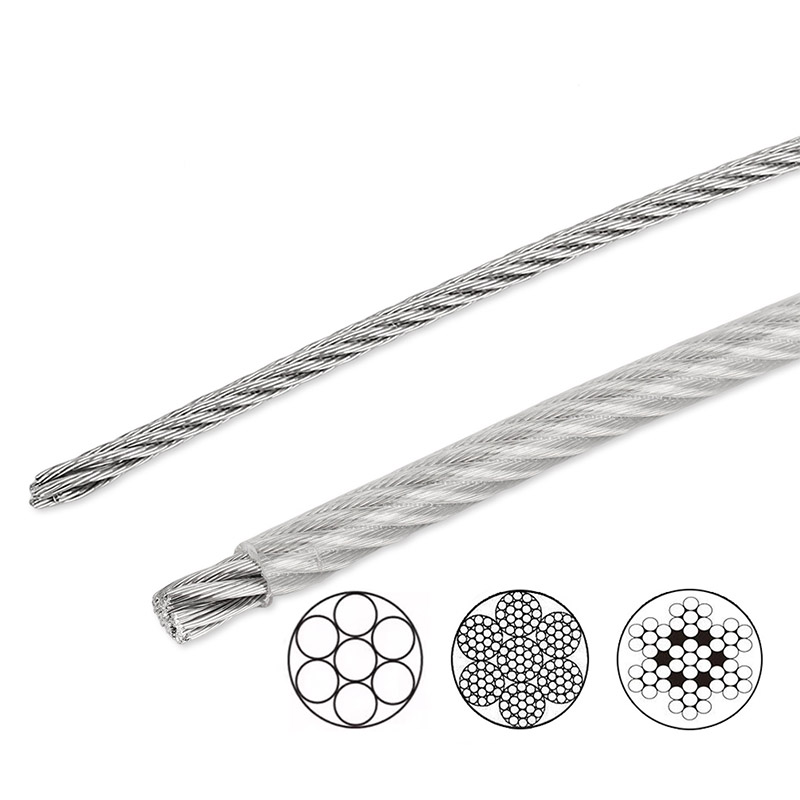

Uniformly Coated Galvanized Steel Wire are widely used in the construction of bridge cables and suspension systems - their corrosion resistance is particularly important in this application. The surface of these wires is covered with a zinc coating of sufficient thickness and even distribution, which not only gives them a shiny silver-gray appearance, but also significantly improves the overall durability of the product, making it able to adapt to more complex usage environments.

Our integrated production process ensures significant price competitiveness. For bulk purchases, we offer an additional 5% discount on orders of 50 tons or more. We collaborate with reliable logistics partners to ensure that the goods are delivered quickly. The wires are wound on sturdy, waterproof wooden or steel reels, so they are not damaged or exposed to moisture during transportation - this ensures that the goods are in good condition upon arrival at the site.

Application Scenario

In the field of power transmission, Uniformly Coated Galvanized Steel Wire is a necessary material for manufacturing structural cores of grounding wires and overhead cables. It has a high tensile strength and can withstand long-term use without any damage. Its sturdy zinc coating can well cope with harsh weather conditions.

Efficient production allows us to sell this high-quality wire at a reasonable price. If you purchase more than 80 tons in bulk, you can also enjoy a customization discount. The wire is packaged very securely and will not spread out. We transport it by sea or by rail, as these two methods offer better cost-effectiveness.

As part of the quality control process, we conduct pre-shipment inspections and also provide relevant test certificates from the rolling mill.

Product Benefits

The key advantage of Uniformly Coated Galvanized Steel Wire lies in its exceptional corrosion resistance. After the hot dip process, a thick zinc layer will be formed, which is closely metallurgically bonded to the substrate. This layer of zinc can provide excellent rust protection and can also resist damage caused by the environment. Galvanized steel wire is an ideal choice for outdoor applications, construction projects and harsh environments, where it meets the critical need for longevity and ensures long-term reliable performance.

Product parameters table

| item | material |

(mm) diameter |

(mm) tolerance |

(Mpa) T/S |

/100d torsion |

(g/m²) weight of zinc coating |

|

Hot dip galvanized steel wire |

60 | 1.0 | +0.03~-0.03 | 105-125 | 18 | 100 |

| 60 | 1.1 | +0.03--0.03 | 105-125 | 18 | 100 | |

| 60 | 1.3 | +0.03~-0.03 | 100-125 | 18 | 130 | |

| 60 | 1.4 | +0.03~-0.03 | 100-125 | 18 | 140 | |

| 60 | 1.6 | +0.04~-0.03 | 100-125 | 18 | 160 | |

| 60 | 1.8 | +0.04~-0.03 | 100-125 | 17 | 180 | |

| 60 | 2.0 | +0.045~-0.035 | 100-125 | 17 | 210 | |

| 60 | 2.2 | +0.045~-0.035 | 100-120 | 17 | 210 | |

| 60 | 2.4 | +0.045~-0.035 | 100-120 | 17 | 230 | |

| 70 | 2.6 | +0.045~-0.035 | 110-130 | 13 | 240 | |

| 70 | 2.8 | +0.045~-0.035 | 110-130 | 13 | 250 | |

| 70 | 3.0 | +0.045~-0.035 | 110-130 | 13 | 260 | |

| 70 | 3.2 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 | 3.4 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 | 3.6 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 |

4.0 |

+0.045~-0.035 |

105-115 |

13 | 260 |