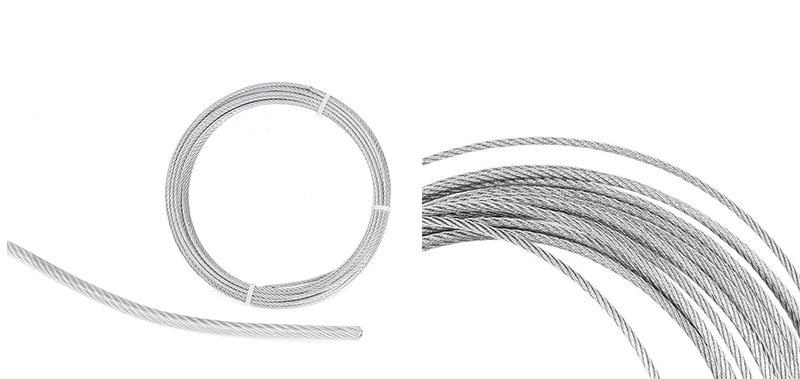

Industrial Strength Galvanized Steel Wire

Send Inquiry

Industrial Strength Galvanized Steel Wire are the basic materials for manufacturing welded nets (used for fences, gabions and concrete reinforcement). This thick zinc coating can keep the net-like structure intact even in corrosive environments such as retaining walls and coastal areas.

Our prices are very competitive in the industry, so you don't have to worry about overpaying. And if you come back again, you can directly use the member discount, which is even more affordable. This steel wire is supplied in a compact, tightly wound roll form, which is easy to handle and transport. We use waterproof and tear-resistant packaging to prevent damage.

All of our products have been certified and can meet or exceed international galvanized steel wire specification standards.

Product Details

In the automotive industry, Industrial Strength Galvanized Steel Wire are used to manufacture the inner rings of tires and other important reinforcing components - strength and corrosion resistance are of utmost importance here. These steel wires have precise dimensional tolerances and a smooth coating, with excellent adhesion.

We offer cost-effective options for automotive suppliers. If your order exceeds 60 tons, the price will be determined based on the quantity you purchase. We adopt a rapid transportation method to meet the requirements of lean production plans. The packaging design ensures that the coil material does not deform and the surface remains clean.

Backed by an IATF 16949 certified quality management system, we provide you with not only products but also exceptional quality and a solid guarantee of traceability. The source of each product is clearly traceable and standards are strictly enforced.

FAQ

Q:Can you produce custom specifications for galvanized steel wire?

A: No problem, just specify your requirements for diameter, tensile strength and zinc coating thickness and we can custom-make your Industrial Strength Galvanized Steel Wire. Our production technology can make galvanized steel wire according to your needs. No matter what special usage you have, we can meet it, and the quality and effect of use are always the same. We welcome your technical specifications for quotation.

Product parameters table

| item | material |

(mm) diameter |

(mm) tolerance |

(Mpa) T/S |

/100d torsion |

(g/m²) weight of zinc coating |

|

Hot dip galvanized steel wire |

60 | 1.0 | +0.03~-0.03 | 105-125 | 18 | 100 |

| 60 | 1.1 | +0.03--0.03 | 105-125 | 18 | 100 | |

| 60 | 1.3 | +0.03~-0.03 | 100-125 | 18 | 130 | |

| 60 | 1.4 | +0.03~-0.03 | 100-125 | 18 | 140 | |

| 60 | 1.6 | +0.04~-0.03 | 100-125 | 18 | 160 | |

| 60 | 1.8 | +0.04~-0.03 | 100-125 | 17 | 180 | |

| 60 | 2.0 | +0.045~-0.035 | 100-125 | 17 | 210 | |

| 60 | 2.2 | +0.045~-0.035 | 100-120 | 17 | 210 | |

| 60 | 2.4 | +0.045~-0.035 | 100-120 | 17 | 230 | |

| 70 | 2.6 | +0.045~-0.035 | 110-130 | 13 | 240 | |

| 70 | 2.8 | +0.045~-0.035 | 110-130 | 13 | 250 | |

| 70 | 3.0 | +0.045~-0.035 | 110-130 | 13 | 260 | |

| 70 | 3.2 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 | 3.4 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 | 3.6 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 |

4.0 |

+0.045~-0.035 |

105-115 |

13 | 260 |