Robustly Guarded Galvanized Steel Wire

Send Inquiry

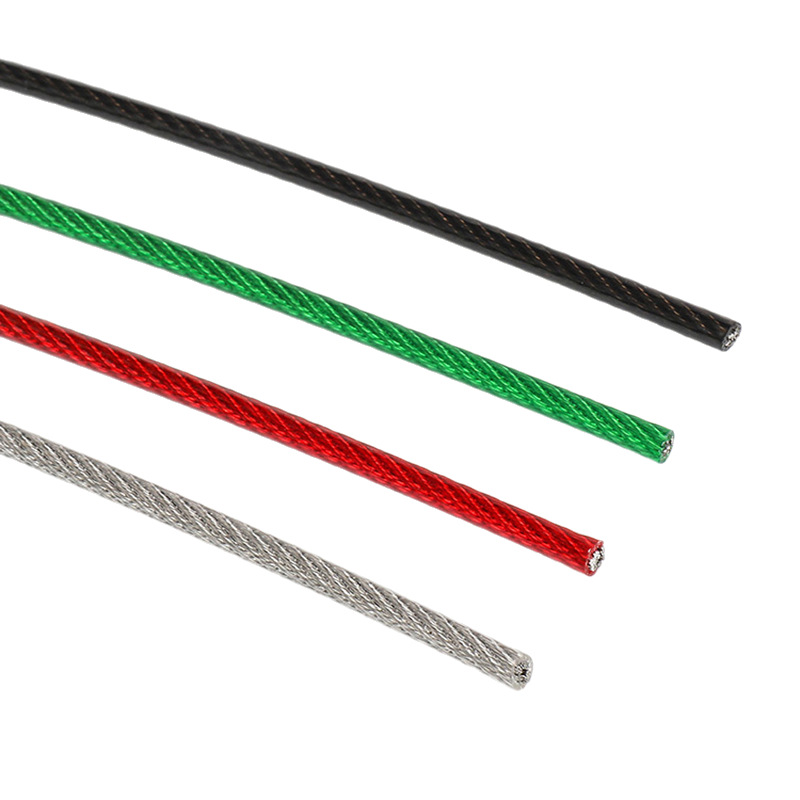

Robustly Guarded Galvanized Steel Wire are key materials for manufacturing overhead power transmission and communication cables - they play a role in bearing weight. This material has high strength and corrosion resistance, so the cables can remain in good condition for several decades.

Our advanced galvanizing technology enables us to offer significant price advantages. Power companies that make large purchases can receive special discount schemes. These steel wires are transported through durable reels and work well in conjunction with the cable production line.

Our factory will conduct size inspections on each piece of every batch of products and conduct sample tensile tests. All data will be recorded in the test certificates provided by us.

Product Details

When manufacturing industrial chains and shackles, Robustly Guarded Galvanized Steel Wire are a common choice. They are highly resilient, capable of withstanding harsh conditions, and do not rust easily. These wires are easy to bend, and their coating is uniform throughout the product.

For the forging and chain manufacturing industries, our prices are very competitive. If you pay for an order of over 25 tons in advance, you can enjoy a 4% discount. We provide reliable and cost-effective transportation services worldwide.

This product undergoes strict quality inspections - such as testing the wrapping and adhesion of the zinc coating. This ensures that it can function properly and be used safely.

FAQ

Q:What packaging options ensure the galvanized steel wire arrives undamaged?

A:We package Robustly Guarded Galvanized Steel Wire on sturdy wooden or steel reels, wrapped in waterproof material with desiccants for moisture protection. This careful packaging prevents coating damage during transit. For international shipments, we ensure the Robustly-Guarded Hot-dip galvanized billet steel wire arrives in perfect condition, ready for your production needs.

Product parameters table

| item | material |

(mm) diameter |

(mm) tolerance |

(Mpa) T/S |

/100d torsion |

(g/m²) weight of zinc coating |

|

Hot dip galvanized steel wire |

60 | 1.0 | +0.03~-0.03 | 105-125 | 18 | 100 |

| 60 | 1.1 | +0.03--0.03 | 105-125 | 18 | 100 | |

| 60 | 1.3 | +0.03~-0.03 | 100-125 | 18 | 130 | |

| 60 | 1.4 | +0.03~-0.03 | 100-125 | 18 | 140 | |

| 60 | 1.6 | +0.04~-0.03 | 100-125 | 18 | 160 | |

| 60 | 1.8 | +0.04~-0.03 | 100-125 | 17 | 180 | |

| 60 | 2.0 | +0.045~-0.035 | 100-125 | 17 | 210 | |

| 60 | 2.2 | +0.045~-0.035 | 100-120 | 17 | 210 | |

| 60 | 2.4 | +0.045~-0.035 | 100-120 | 17 | 230 | |

| 70 | 2.6 | +0.045~-0.035 | 110-130 | 13 | 240 | |

| 70 | 2.8 | +0.045~-0.035 | 110-130 | 13 | 250 | |

| 70 | 3.0 | +0.045~-0.035 | 110-130 | 13 | 260 | |

| 70 | 3.2 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 | 3.4 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 | 3.6 | +0.045~-0.035 | 108-120 | 13 | 260 | |

| 70 |

4.0 4.5 |

+0.045~-0.035 +0.045~-0.035 |

105-115 105-115 |

13 | 260 |