UN floating spring screws

Send Inquiry

UN floating spring screws are typically made from medium or high-carbon steel,like grades 8.8, 10.9, or 12.9,when strength matters most. If rust is a concern, they use stainless steel instead (common types are A2/304 or A4/316).

The spring washer isn't added later,it's formed from the same piece of metal. After shaping, it gets heat-treated (tempered). This step is important because it gives the washer its springy action and flexibility.

Installation and Maintenance

To install UN floating spring screws, you just drive them into a pilot hole that’s the right size. As the knurled part goes in, it pushes the material aside, which locks it in place. Use enough torque to compress the spring washer completely and get the right clamping force.

Because of the way they’re designed to lock and the spring feature, you usually don’t need to retighten them later or use any special lubrication. For maintenance, just check them occasionally for rust or damage. If a screw is messed up, it’s best to replace it.

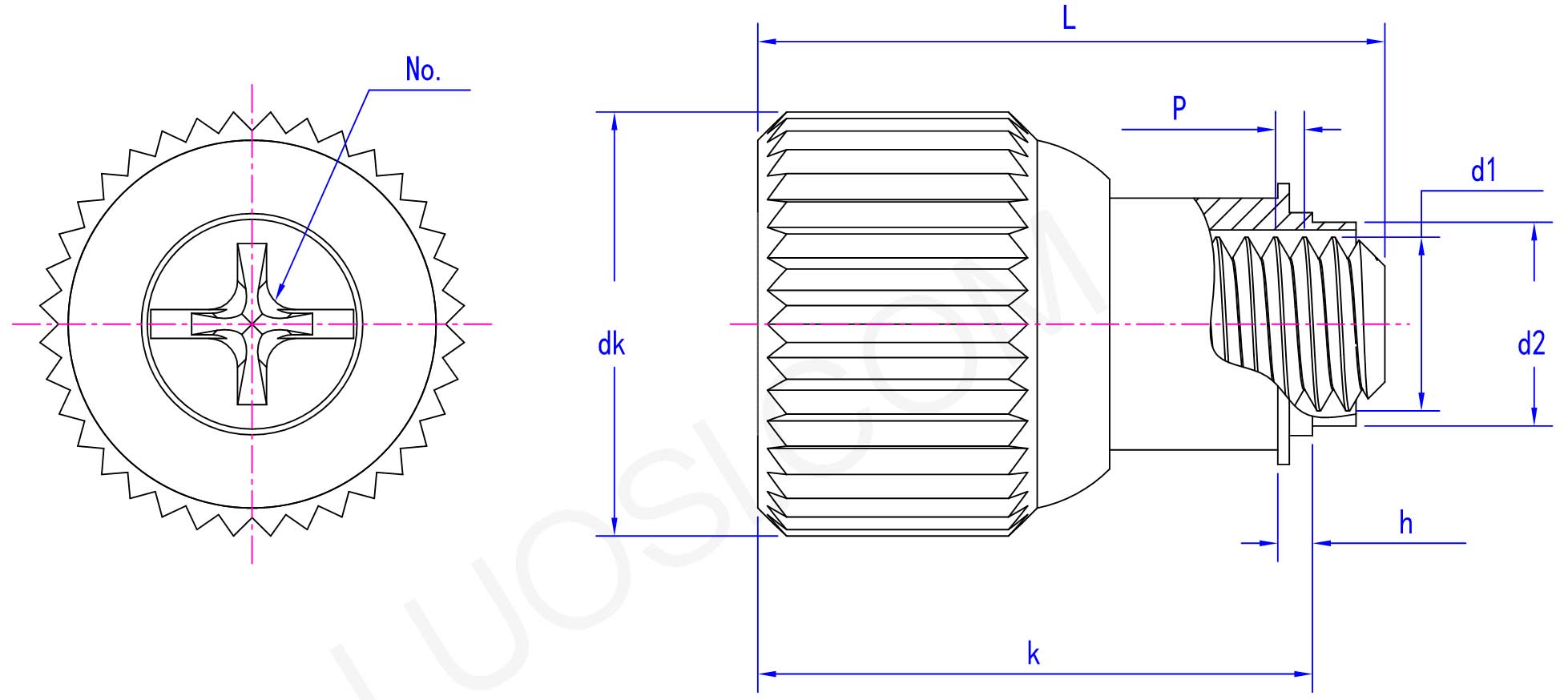

Product parameters

| Mon | 440 | 632 | 832 | 032 |

| P | 40 | 32 | 32 | 32 |

| d1 | #4 | #6 | #8 | #10 |

| d2 min | 0.184 | 0.029 | 0.263 | 0.263 |

| d2 max | 0.189 | 0.214 | 0.267 | 0.267 |

| dk max | 0.423 | 0.463 | 0.522 | 0.522 |

| dk min | 0.404 | 0.443 | 0.502 | 0.502 |

| h | 0.038 | 0.038 | 0.038 | 0.038 |

| k | 0.469 | 0.606 | 0.638 | 0.638 |

| No. | 1 | 2 | 2 | 2 |

Advantages

UN floating spring screws can save you a lot of money. They cut out the need for extra stuff like welding wire, gas, or rivets. Compared to welding, they use less energy, and unlike rivets, you don’t need to reach the backside of the material to install them.

Putting them in is quick,just use basic press tools (like a C-frame or robot), which cuts down on labor costs. That makes them really efficient for mass production.