Metric Type F 12 Piont Flange Screw

Send Inquiry

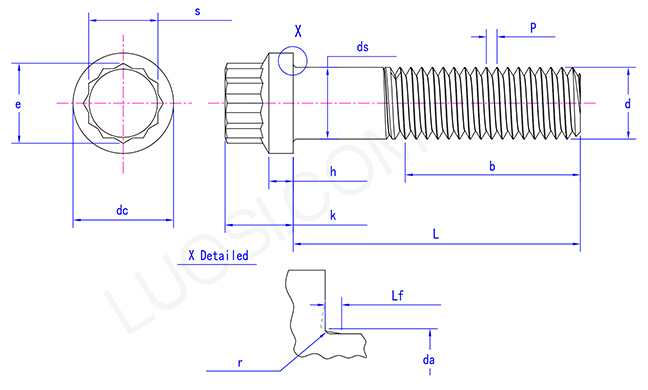

The head design of metric type F 12 piont flange screw is very special, with 12 corners. At its bottom, there is an F-shaped flange plate. This flange plate is equivalent to a large gasket, which can increase the contact area with the connected material and make the connection more stable.

Features

The feature of metric F type 12 piont flange screw is the unique 12-corner plus F-type flange plate structure. The 12 corners provide more force application points, making the tightening operation more precise and smooth. The F-type flange not only disperses pressure but also prevents screws from sinking into the fixed material, further enhancing the stability of the connection.

Metric type F 12 piont flange screws with sawtooth flange. When tightened, these teeth will bite the surface, preventing mechanical equipment (such as conveyor belt rollers or pump brackets) from loosening due to vibration. You don't need to add any extra locking washers.

Metric type F 12 point screws install faster on uneven surfaces. The serrated bottom can make up for minor defects. It is very useful when connecting bolts to cast iron or textured metals, as smooth flanges may slip off. Its grip is stronger. The serrated bottom can be embedded with metal and is more resistant to vibration than smooth flange-type screws. It is often used in agricultural equipment or compressor bases.

Product parameters

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | M24 | M30 | M36 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 3 | 3.5 | 4 |

| ds max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 | 30 | 36 |

| ds min | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | 32.67 | 29.67 | 35.61 |

| s max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 | 30 | 36 |

| s min | 4.79 | 5.79 | 7.78 | 9.78 | 11.79 | 13.79 | 15.81 | 19.82 | 23.75 | 29.72 | 35.7 |

| e min | 5.6 | 6.7 | 9 | 11.2 | 13.5 | 15.8 | 18 | 22.5 | 27 | 33.8 | 40.5 |

| dc max | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 30.33 | 36.39 | 45.39 | 54.46 |

| dc min | 8.27 | 9.77 | 12.72 | 15.69 | 17.67 | 20.67 | 23.62 | 29.55 | 35.52 | 44.52 | 52.75 |

| h max | 2.25 | 2.7 | 3.6 | 4.5 | 5.4 | 6.3 | 7.2 | 9 | 10.8 | 13.5 | 16.2 |

| h min | 2 | 2.45 | 3.35 | 4.13 | 5.03 | 5.93 | 6.83 | 8.5 | 10.3 | 13 | 15.6 |

| k max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 | 30 | 36 |

| k min | 4.88 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | 23.67 | 29.67 | 35.57 |

| da max | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 22.4 | 26.4 | 33.4 | 39.4 |

| Lf max | 0.6 | 0.68 | 1.02 | 1.02 | 1.87 | 1.87 | 1.87 | 2.04 | 2.04 | 2.89 | 2.99 |

| r min | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 1 | 1 |

Metric type F 12 piont flange screws are suitable for repairing damaged holes. The serrated structure can act as an anchor at the worn thread and can be used as a temporary fix for old equipment before maintenance. They can withstand thermal cycling. The serrated flange maintains grip when the metal expands or contracts, making it highly suitable for exhaust manifolds or oven components.