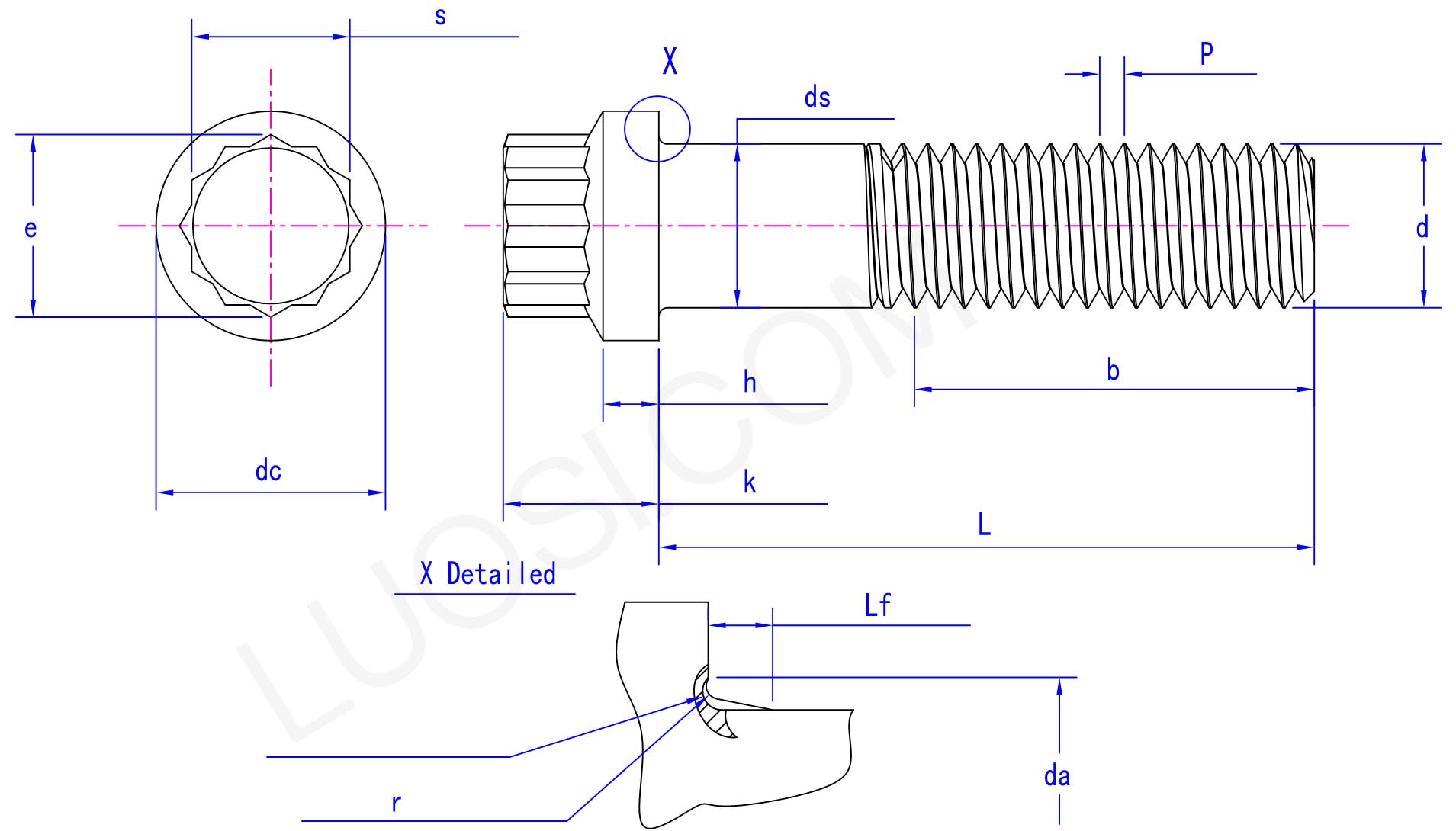

Metric Type U 12 Piont Flange Screw

Send Inquiry

The metric type U 12 piont flange screw has 12 corners at the head. When tightened, it has a larger contact area and can apply a greater torque. There is a U-shaped flange plate under the screw, which can increase the contact area with the connected part and disperse the pressure.

Features and parameters

Metric type U 12-point screws are resistant to salt spray corrosion. The bottom cut design is often used in stainless steel, which can reduce crevice corrosion. Flange sealing surfaces, they are ideal choices for ship railings or coastal infrastructure. They can prevent loosening. The serrated flange bottom surface has a meshing surface, which is suitable for industrial vibrators or generator brackets that do not require locking washers.

The metric type U 12 piont flange screws is used to fasten the turbine exhaust manifold. Manifold leakage will reduce the turbine efficiency. They can withstand a thermal cycle of 900°C. The U-shaped groove can prevent the flange from warping when tightened. When nickel anti-sticking agent is applied, the copper paste will burn off. Replace it every 50,000 miles driven; Thermal fatigue can cause the exhaust pipe to burst.

The metric type U 12-point screws are used to fix the gearbox covers of wind turbines. Turbine vibration can cause traditional screws to retreat. They can lock the cover plate for more than 20 years. The bottom cut part can play a role in shock absorption. When using a 12-point torque multiplier at a height, insufficient tightening can cause dust to enter and damage the gears.

The metric type U 12 piont flange screw has an extremely strong fastening force. The 12-angle design enables it to withstand greater torque when tightened. Additionally, the U-shaped flange increases friction, making it difficult to loosen even in a vibrating environment. They are very reliable and can keep the connection parts stable all the time.

Product parameters

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | M24 | M30 | M36 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 3 | 3.5 | 4 |

| ds max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 | 30 | 36 |

| ds min | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | 23.67 | 29.67 | 35.61 |

| s max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 | 30 | 36 |

| s min | 4.79 | 5.79 | 7.78 | 9.78 | 11.79 | 13.79 | 15.81 | 19.82 | 23.75 | 29.72 | 35.7 |

| e min | 5.6 | 6.7 | 9 | 11.2 | 13.5 | 15.8 | 18 | 22.5 | 27 | 33.8 | 40.5 |

| dc max | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 30.33 | 36.39 | 45.39 | 54.46 |

| dc min | 8.27 | 9.77 | 12.72 | 15.69 | 17.67 | 20.67 | 23.62 | 29.55 | 35.52 | 44.52 | 52.75 |

| h max | 2.25 | 2.7 | 3.6 | 4.5 | 5.4 | 6.3 | 7.2 | 9 | 10.8 | 13.5 | 16.2 |

| h min | 2 | 2.45 | 3.35 | 4.13 | 5.03 | 5.93 | 6.83 | 8.5 | 10.3 | 13 | 15.6 |

| k max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 24 | 30 | 36 |

| k min | 4.88 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | 23.67 | 29.67 | 35.57 |

| da max | 6.2 | 7.5 | 10 | 12.5 | 15.2 | 17.7 | 20.5 | 25.5 | 30.7 | 38.5 | 46.2 |

| Lf max | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 | 3.2 | 3.2 | 4.5 | 4.5 |

| r max | 0.25 | 0.26 | 0.36 | 0.45 | 0.54 | 0.63 | 0.72 | 0.89 | 1.07 | 1.33 | 1.6 |

| r min | 0.1 | 0.11 | 0.16 | 0.2 | 0.24 | 0.28 | 0.32 | 0.4 | 0.48 | 0.61 | 0.73 |