Type TD Projection Weld Studs

Send Inquiry

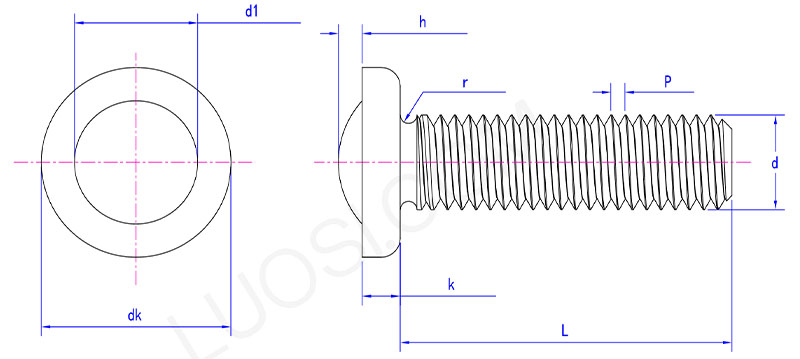

The type TD projection weld studs have a round head, with a threaded rod body attached below. The transition area between the head and the rod is very smooth and regular. There are various thread sizes and lengths available, which can be adapted to various scenarios requiring welding fixation.

Product parameters

Mon

#6

#8

#10

1/4

5/16

3/8

1/2

P

32

32

24

20

18

16

13

dk max

0.26

0.323

0.385

0.51

0.63

0.755

1.005

dk min

0.24

0.303

0.368

0.485

0.605

0.725

0.975

k max

0.046

0.052

0.068

0.083

0.099

0.114

0.146

k min

0.036

0.042

0.058

0.073

0.089

0.104

0.136

d1 max

0.143

0.169

0.195

0.255

0.317

0.38

0.505

d1 min

0.133

0.159

0.185

0.245

0.307

0.37

0.495

h max

0.027

0.028

0.028

0.031

0.031

0.033

0.035

h min

0.022

0.023

0.023

0.026

0.026

0.028

0.03

r max

0.02

0.025

0.03

0.04

0.045

0.05

0.06

Application

The TD projection weld studs are commonly used in the automotive industry. When manufacturing components such as car bodies and chassis, it is common to fix various small parts in place. For instance, installing the locking mechanisms on the car doors or fixing the small supports on the chassis. After using these methods, the components of the car will not shake or make abnormal noises when driving.

Type TD projection weld studs are different from ordinary screws. With this special head shape, during the welding process, the current can be more concentrated and the heat distribution is more uniform. The quality of the welded joint is particularly stable. Moreover, the thread is processed very neatly, and it is very smooth when the nut is tightened, without getting stuck.

TD type projection weld studs is used in home appliance assembly. For example, when assembling the outer shell of a washing machine, you need to fix the motor bracket inside, weld this screw column onto the outer shell, then install the bracket upwards and tighten the nut. The shelves in the refrigerator are fixed, and the small components of the air conditioner's outdoor unit are installed. Using this method for welding makes it both sturdy and convenient.

Product Features

Type TD projection weld studs offer both convenience and strength in welding. When welding, it's extremely convenient. Just place the weldment on it, no need to fuss about alignment. Once powered on, the screws and the weldment will be fused together very quickly, with extremely high efficiency. Moreover, the welding is extremely sturdy. Whether it is pulled or shaken, it will not easily come loose.