Threaded Weld Studs

Send Inquiry

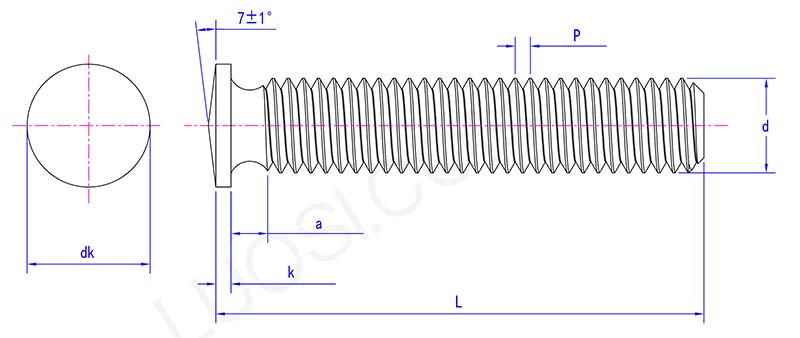

Threaded weld studs are a type of screws that need to be welded under gas protection. They are metal rods with threads on the whole, and the head may be flat, round, or may have small protrusions, depending on the model. They can be paired with parts of different thicknesses.

Product advantage

The greatest advantage of threaded weld studs is that the welding area is less prone to rusting. During the welding process, there will be gases such as argon or carbon dioxide surrounding the welding point, keeping the air out. The oxygen and nitrogen in the air will not enter the welding point, so the area won't rust easily. Moreover, the weld is quite strong and won't fall off even when forcibly pulled or when the parts shake.

Product parameters

Mon

M3

M4

M5

M6

M8

M10

P

0.5

0.7

0.8

1

1.25

1.5

dk max

4.15

5.15

6.15

7.15

9.15

11.15

dk min

3.85

4.85

5.85

6.85

8.85

10.85

k max

1.4

1.4

1.4

1.4

1.4

1.4

k min

0.7

0.7

0.8

0.8

0.8

0.8

a max

1.5

1.5

2

2

2

2

Product applications

Threaded weld stud is used in food processing equipment. Items like blenders and conveyor belts will be used. These devices need to be washed with water frequently, and some even come into contact with acid or alkali cleaners. The ordinary screw welds are prone to rusting. If the rust particles get into the food, it will cause problems. For example, the support brackets of the conveyor belt are fixed. This involves welding these screws onto the equipment frame. The welding seams are free from rust. After the brackets are installed, the equipment can operate normally.

Threaded weld studs are used in the medical device production line. For example, the conveyor belt for producing infusion sets needs to be securely fixed. The equipment must be clean and free from rust that could contaminate the products. Attach them to the metal frame of the equipment, then fix the conveyor belt track properly. The welding seams should be smooth and free of rust, meeting hygiene requirements. During the operation of the equipment, the track will not shake, and the infusion device parts can be accurately conveyed.

The weld studs are used for automotive exhaust pipe components. The temperature around the car exhaust pipe is high, and it also comes into contact with the moisture and impurities in the exhaust gas. The screws that fix the exhaust pipe need to be rust-resistant. Use them to attach the clamps to the vehicle body, then clamp the exhaust pipe. The welding points will not oxidize or rust under the gas protection. Even if the exhaust pipe gets hot and then cools down repeatedly, the welding points will not crack, and the exhaust pipe will not loosen and make noise.