Structural Grade Core Penetrating Rivet

Send Inquiry

Each batch of Structural Grade Core Penetrating Rivet undergoes final quality checks before leaving the factory - we conduct this check before shipment. Part of this inspection involves randomly selecting samples for destructive testing: we install some rivets and test them to see if they can withstand tensile penetration and shear forces, just to ensure they function properly. This final check ensures that the core-through rivets we send to you meet the technical requirements and performance standards we have promised.

Excellent product quality

Our factory and the Structural Grade Core Penetrating Rivet have both received international recognized quality certifications, such as ISO 9001 certification. If you need to view these certificates, just let us know. These certificates indicate that we place great emphasis on maintaining the stability of quality and the reliability of the production process. We also manufacture through-boltings according to different industry standards, so that they can be applicable in fields such as automobiles, aerospace, and construction - in these fields, compliance with such certifications is essential.

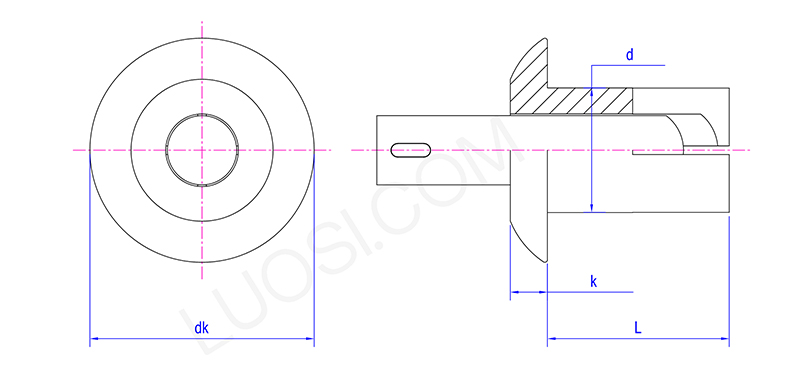

Product Parameters

| Mon | 1/8 | 5/32 | 3/16 | 1/4 |

| d max | 0.127 | 0.158 | 0.19 | 0.252 |

| d min | 0.121 | 0.152 | 0.184 | 0.246 |

| dk max | 0.262 | 0.328 | 0.394 | 0.525 |

| dk min | 0.238 | 0.296 | 0.356 | 0.475 |

| k max | 0.064 | 0.077 | 0.09 | 0.117 |

| k min | 0.054 | 0.067 | 0.08 | 0.107 |

FAQ

Q: How does the cost-effectiveness of Structural Grade Core Penetrating Rivet compare to welding or screws?

A: Structural Grade Core Penetrating Rivet are really cost-effective over the long run. First off, you don’t have to pay for pre-punching or drilling holes, or for deburring afterward. If you compare them to welding, you don’t need skilled workers, equipment to suck out fumes, or extra finishing work. And versus screws, they install way faster—plus the joint they make is vibration-proof, so it won’t come loose. All this cuts down on total assembly time and makes your product more reliable, which lowers your overall production costs.