Single Step Core Penetrating Rivet

Send Inquiry

If the Single Step Core Penetrating Rivet part are installed correctly and in an appropriate environment, a sealed joint can be formed. This is because the core shaft will break and seal the core part. Now let's talk about packaging: A single packaging box alone cannot be completely waterproof, but the large main packaging box and pallets are always wrapped with waterproof polyethylene film. During storage and transportation, the rivet box can effectively prevent moisture, thereby preventing the rivets from rusting or corroding.

Strict quality inspection

We strictly control the quality of each Single Step Core Penetrating Rivet, using a complete process to ensure its excellent quality. From selecting raw materials to packaging the final product, each batch of products undergoes strict inspections: we simultaneously carry out three quality inspections: product dimension measurement, mechanical strength testing, and material composition verification; in the production line, we use statistical process control (SPC) to directly ensure the consistency of all processes. This rigorous working approach ensures that each through-bolt meets our high-performance standards.

Product Benefits

The way you install a Single Step Core Penetrating Rivet is set up to keep pre-finished materials from getting damaged too much. The rivet goes through the base material in a controlled, small area. Now, you will get a little bit of disruption to the coating right around the rivet head—you can’t avoid that entirely—but it’s way less damage than what you’d get from drilling or punching a hole. This helps keep the whole assembly’s corrosion protection working and keeps it looking good.

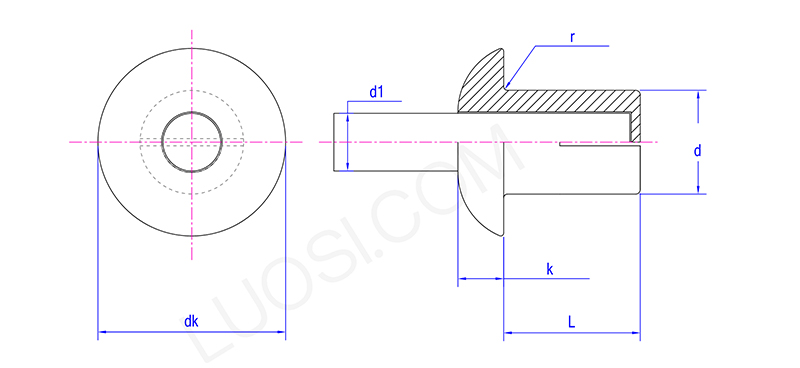

Product Parameters

| Mon | Φ3 |

Φ4 |

Φ5 |

Φ6 |

Φ6.4 |

| d min | 2.94 | 3.92 | 4.92 | 5.92 | 6.32 |

| d max | 3.06 | 4.08 | 5.08 | 6.08 | 6.48 |

| dk max | 6.24 | 8.29 | 9.89 | 12.35 | 13.29 |

| dk min | 5.76 | 7.71 | 9.31 | 11.65 | 12.71 |

| k max | 1.4 | 1.7 | 2 | 2.4 | 3 |

| d1 | 1.8 | 2.18 | 2.8 | 3.6 | 3.8 |

| r max | 0.5 | 0.5 | 0.7 | 0.7 | 0.7 |