Consistent Core Penetrating Rivet

Send Inquiry

In the fields of construction and structural metal processing, Consistent Core Penetrating Rivet are extremely strong in withstanding shear forces and tensile forces. For this reason, they are highly suitable for constructing frameworks, bridges and storage systems. They excel at connecting high-strength steel and aluminum alloys - especially in those areas where welding is difficult or would make the material fragile. With outstanding durability and reliability, these rivets can effectively lock structural stability, achieving the triple guarantee of "long-lasting use, firm connection, and worry-free safety". They can meet the demanding requirements of construction and industrial projects, and have proven themselves capable of performing tasks exceptionally well.

Product Benefits

The transportation industry - such as railway carriages and aerospace products - extensively uses Consistent Core-penetrating rivet. These Consistent Core Penetrating Rivet are lightweight yet highly durable, which is why they are so useful. When assembling vehicle body components and interior parts, reducing weight is crucial for improving fuel efficiency. These rivets help achieve this goal without compromising safety or durability. They meet the industry's strict standards for vibration resistance and durability. This means that key components can remain securely fixed even under extremely harsh operating conditions.

FAQ

Q: How does the installation process for a Consistent Core Penetrating Rivet differ from a standard rivet?

A:The process of installing a Consistent Core Penetrating Rivet is very similar to that of installing a regular blind bolt - you both need to use ordinary pneumatic or manual riveting tools. The main difference lies in the magnitude of the force required: the force you need to apply is much greater. This force pushes the hardened core of the bolt into the material, causing it to pass through. Therefore, you don't need to drill or bore beforehand. This makes the assembly process faster and reduces labor costs in mass production.

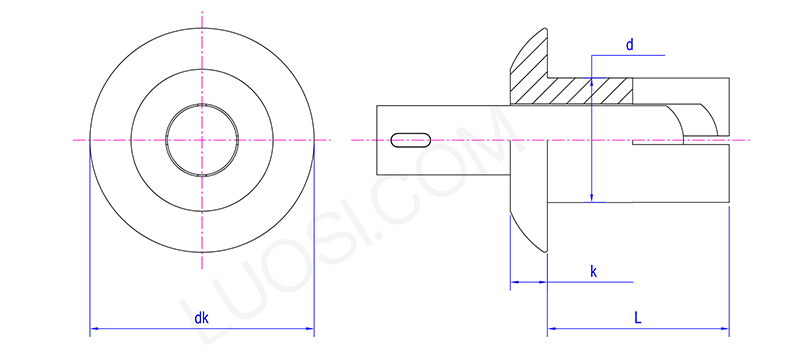

Product Parameters

| Mon | 1/8 | 5/32 | 3/16 | 1/4 |

| d max | 0.127 | 0.158 | 0.19 | 0.252 |

| d min | 0.121 | 0.152 | 0.184 | 0.246 |

| dk max | 0.262 | 0.328 | 0.394 | 0.525 |

| dk min | 0.238 | 0.296 | 0.356 | 0.475 |

| k max | 0.064 | 0.077 | 0.09 | 0.117 |

| k min | 0.054 | 0.067 | 0.08 | 0.107 |