Efficiency Optimized Core Penetrating Rivet

Send Inquiry

This packaging for Efficiency Optimized Core Penetrating Rivet is very sturdy. We tightly pack them into sturdy double-layer cardboard boxes or durable plastic containers - so that they won't move around during transportation. For larger quantities of transportation, each box of these rivets will be safely placed on a pallet and wrapped with stretch film. Thus, no matter where they are transported to (even to international destinations), they can arrive intact.

Sturdy packaging

Because we have carried out strict packaging for the product, the situation where the Efficiency Optimized Core Penetrating Rivet are damaged during transportation is extremely rare. These rivets are themselves sturdy metal components - they can withstand a certain amount of impact force. We also test our packaging to ensure it can withstand the common challenges of shipping – like vibration, compression, and potential drops. Therefore, you can rest assured that the core penetrating rivets you ordered will be delivered intact and ready for immediate use at any time.

Professional tools needed

To install a Efficiency Optimized Core Penetrating Rivet, you need a high-power, standard jaw-type rivet gun. The tool has to be able to generate enough pulling force—this force pulls the mandrel and pushes the core through the workpieces. We’ll suggest specific tool models based on how big your rivets are and how thick the material is. In addition, we can provide you with professional advice on the optimal tool selection based on your actual production volume and production line efficiency data, helping you to accurately match the tool with the production scenario.

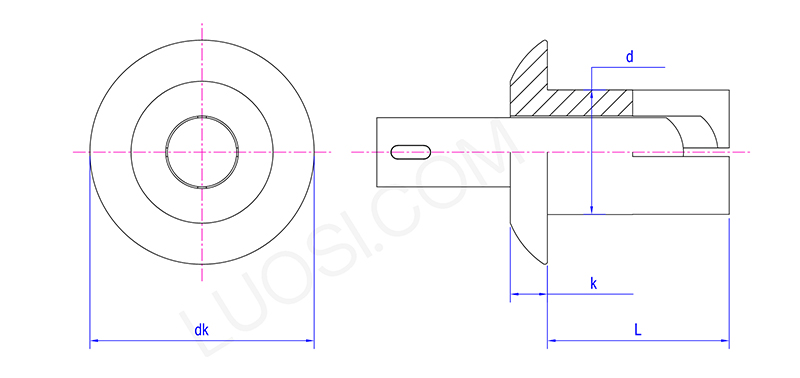

Product Parameters

| Mon | 1/8 | 5/32 | 3/16 | 1/4 |

| d min | 0.127 | 0.158 | 0.19 | 0.252 |

| d max | 0.121 | 0.152 | 0.184 | 0.246 |

| dk max | 0.262 | 0.328 | 0.394 | 0.525 |

| dk min | 0.238 | 0.296 | 0.356 | 0.475 |

| k max | 0.064 | 0.077 | 0.09 | 0.117 |

| k min | 0.054 | 0.067 | 0.08 | 0.107 |