Steel Eye Bolts

Send Inquiry

How long Steel Eye Bolts last really depends on how well you take care of them. You should check the threads regularly to make sure there’s no dirt or other stuff stuck in there. And put some lithium-based grease on them to keep friction down.

If you’re using the bolts in a place where things rust easily, go for stainless steel ones or ones with a protective coating. After they’ve been exposed to the elements, rinse them with clean water. Don’t tighten them too much, lest you’ll mess up the threads. Just use a torque wrench, then set it according to the manufacturer recommends.

If a bolt looks stretched out, has cracks, or has little pits on the surface that is time to replace it. For bolts that get used a lot, figure out how often you need to lubricate them based on how hard they’re working. Do these things, and the bolts will work well and won’t break when you least expect it.

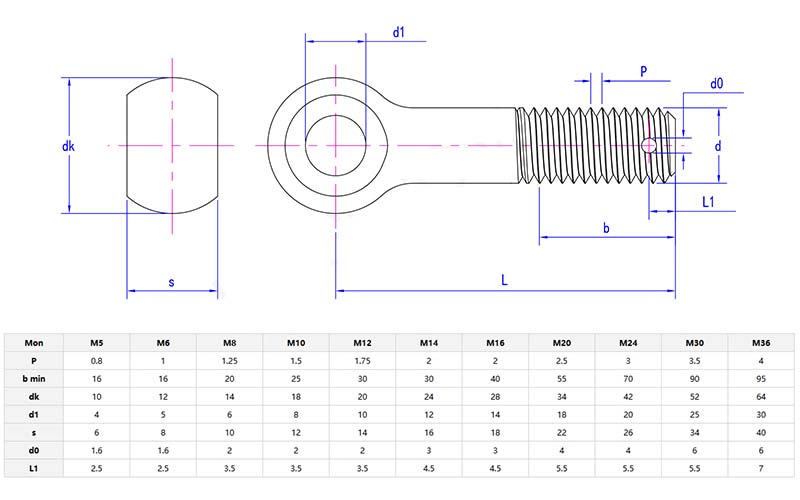

Product details

Regular Steel Eye Bolts are useful, but you can also get them customized. Some have hollow centers so you can run wires through them. Anti-backlash nuts help with getting really precise positioning. And there are ones with modular ends, which makes it easy to swap them out.

You can also choose custom threading, use special materials, for example, Inconel if it gets super hot, or even add RFID tags to keep track of them. Original equipment manufacturers (OEMs) work with engineers to make bolts that are just right for specific uses. Like, they can manufacture non-magnetic bolts for MRI machines or flat bolts that fit in tight spaces.

You can customize them so much, then these bolts are a great option when you have a unique technical problem to solve.

Q&A

Q: How often should the Steel Eye Bolts be inspected for maintenance?

A: Check the bolt every 3 to 6 months. How often you should do it depends on how much you use it. Look for signs of the threads wearing out, rust, or if it's getting loose because of vibration. Tighten it again to the right level (like 50 to 80 Nm) and put some lubricant on the part that pivots.