Pan Head Stud

Send Inquiry

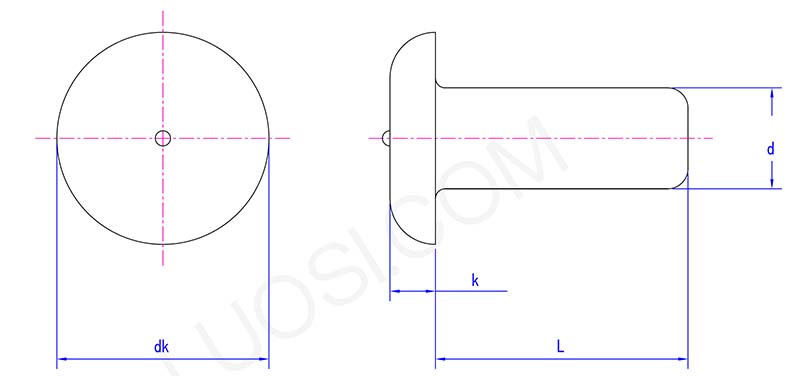

The pan head studs have a circular shape, slightly resembling a dome, and are used for fixing components. The design of the crown makes it appear more rounded and has a larger surface area. They are suitable for use in environments that are prone to moisture or have a slight corrosive nature.

Product features

The disc-shaped head of this stud is circular, with a rounded edge that won't cause injury and is safer to use. The head size is relatively large, and when tightening, it can be operated conveniently with ordinary tools, without the need for special tools. Its material is diverse, enabling it to meet different environmental requirements.

The top of the pan head stud is circular, resembling a shallow dome. After welding, it will slightly protrude. If there is a need to leave space below the head for placing washers or parts, this design will be very practical. In most factories, this kind of situation where height is not an issue is quite common.

These studs are very easy to identify. Their dome-shaped heads are smooth and lack sharp corners. This makes them less likely to hook onto nearby wires or hoses. For equipment with sharp edges that need to be protected, or in confined spaces, they are an ideal choice.

The curvature of pan head studs is better able to withstand stress compared to flat head screws. When an object vibrates or is pulled to one side, this dome-shaped structure can withstand greater force before bending. It is highly suitable for installing pumps, motors or any objects that may shake.

Product parameters

Mon

1/16

3/32

1/8

5/32

3/16

7/32

1/4

5/16

3/8

d max

0.065

0.097

0.128

0.159

0.19

0.222

0.253

0.316

0.378

d min

0.061

0.093

0.124

0.155

0.186

0.218

0.249

0.312

0.374

dk max

0.131

0.196

0.262

0.328

0.394

0.459

0.525

0.656

0.787

dk min

0.119

0.178

0.238

0.296

0.356

0.415

0.475

0.594

0.713

k

0.027

0.04

0.054

0.067

0.08

0.093

0.107

0.133

0.161