Square Nuts On Edge

Send Inquiry

Square nuts on edge are made from alloy steels,like Grade 8 or Class 10.9,or medium carbon steels, and sometimes stainless steel (A2/A4). They get their strength from the specific metal makeup and careful heat treatments, things like quenching and tempering. This controlled treatment makes the material’s yield and tensile strength a lot better. That way, these nuts can handle really strong clamping forces and tough working conditions without bending or breaking. And that’s what makes them different from lower-grade ones, basically.

Advantage

Square nuts on edge are made for high pre-load uses. They don’t come loose from vibration, which is good. Their square shape gives a good grip, and when put in right, it keeps them from spinning in square holes or against flat surfaces. That means they stay tight and last, which is important in high-stress spots.

Application

Square nuts on edge are important parts in heavy-duty fields. They’re used a lot in steel structure frames, putting together heavy machines, rail track fasteners, farm equipment, mining setups, and bridge building. They can take high preload and don’t loosen from vibration, which makes them good for bolted connections in frames, brackets, channels,like Unistrut,and any place where a square hole locks them in well. That way, the connections stay solid for a long time.

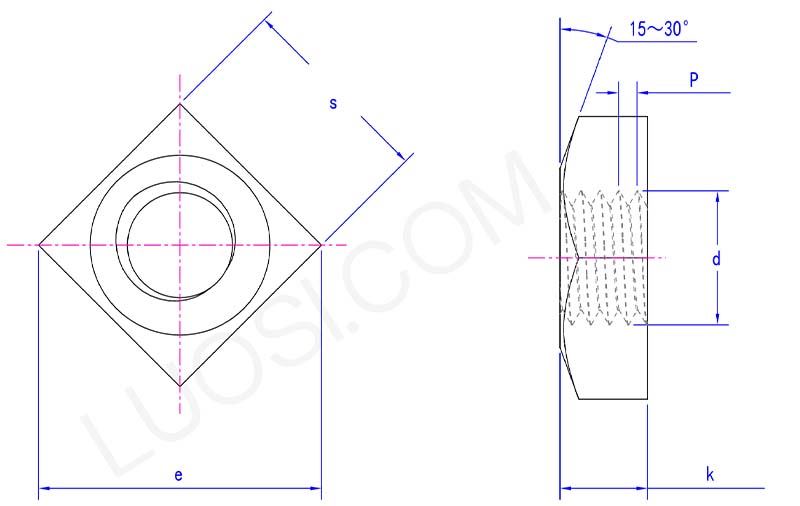

|

Mon |

M10 | M12 |

|

P |

1.5 | 1.75 |

|

e max |

24 | 26.9 |

|

e min |

21.54 | 24.03 |

|

k max |

8 | 10 |

|

k min |

7.42 | 9.42 |

|

s max |

17 | 19 |

|

s min |

16.57 | 18.48 |