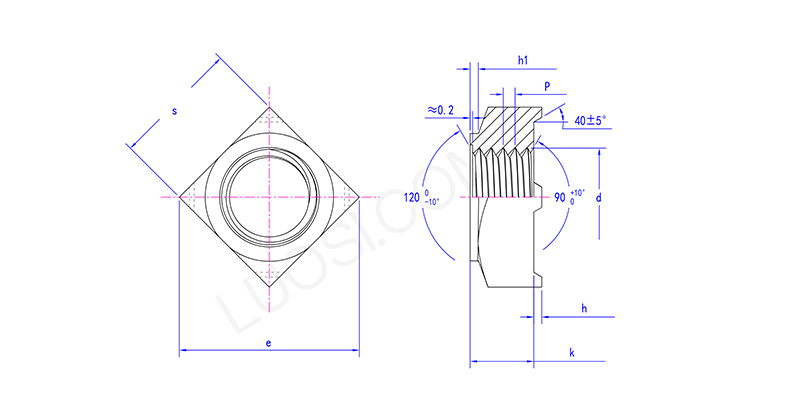

High Precision Square Weld Nuts

Send Inquiry

High Precision Square Weld Nuts are mainly attached with projection welding, which is a type of resistance welding. Electric current and pressure are focused on the nut’s projections. This makes them heat up fast and melt into the base metal.

Since welding results directly depend on how well the nut characteristics (material, size) match the properties of the parent material (thickness or type), core equipment settings (such as current, time, and pressure) must be adjusted accordingly if a high-quality weld is to be achieved.

It’s also important to line them up right and make sure the surfaces are clean, with no scale. That way, the welds are consistent and strong, so the nut works reliably.

Product Details

High Precision Square Weld Nuts have clear advantages over rivet nuts or clinch nuts. They’re a permanent threaded part that can’t be removed, and they have really high pull-out and torque-out strength. The backside is flush, which works well for smooth surfaces or tight spaces.

Installing them is quick, and you can automate it on production lines. Most importantly, they spread out the load well across their square base. That means less stress on thin sheet metal, so they’re better for high-load uses where resisting vibration matters a lot.

FAQ

Q: Do you offer spatter-resistant coatings on your High Precision Square Weld Nuts to minimize cleaning requirements?

A:Yep, we have special coatings for our carbon steel High Precision Square Weld Nuts that resist spatter—like a thin copper layer or our own anti-spatter treatments. This coating cuts down a lot on weld spatter sticking to the nut’s surface and threads during projection welding. That means you don’t have to clean as much after welding, and it keeps the threads protected. Just ask for this option when you order the square weld nuts.

| Mon | 7/16 |

| P | 20 |

| e min | 0.731 |

| h max | 0.051 |

| h min | 0.043 |

| h1 min | 0.049 |

| h1 max | 0.086 |

| k max | 0.351 |

| k min | 0.337 |

| s max | 0.663 |

| s min | 0.646 |