Spring Screws

Send Inquiry

Spring screws are mostly made from good alloy steels,think grades like 4140, 6150, or 8650 or stainless steels like 304 or 316. We pick these materials for solid reasons. They give you a strong combo: high strength, good resistance to getting tired from bending loads (fatigue resistance), and the ability to spring back properly. You need all that for the spring action in the screws to actually work.

Here's the deal with the alloy steels: they usually get heat treated (that's heating and cooling them in specific ways) to hit the right hardness and get that essential springiness. Stainless steel is rust-resistant and corrosion-resistant, and the screws can be bent multiple times under normal forces without deforming or breaking.

Application

Spring screws are used in a lot of tough industries where things need to hold up. You’ll see them in car engines and transmissions (like valve covers or oil pans), in airplane parts and jet engines, in heavy machinery that vibrates all the time, in high-performance electronics that need a solid ground, in precision tools, and even in high-end furniture mechanisms.

Basically, anywhere there’s vibration, temperature changes, moving loads, or safety is a big deal,if regular screws might loosen up on their own, that’s where the screws come in. They keep things tightly fastened for a long time without needing someone to retighten them by hand.

Customize

Q: Can you customize the dimensions or load characteristics?

A:Yeah, customizing spring screws are something we do a lot. We can adjust important bits like how thick the wire is, how many coils there are, the free length, the outer width, and the spring rate (basically, how stiff they are) to fit what you need. Whether that's about the force required, fitting into a tight space, or making them do a specific job,we can handle it.

Just tell us exactly what you need, or even better, send us a sample part. Then we'll make spring screw that slot right into your component and work right in your setup.

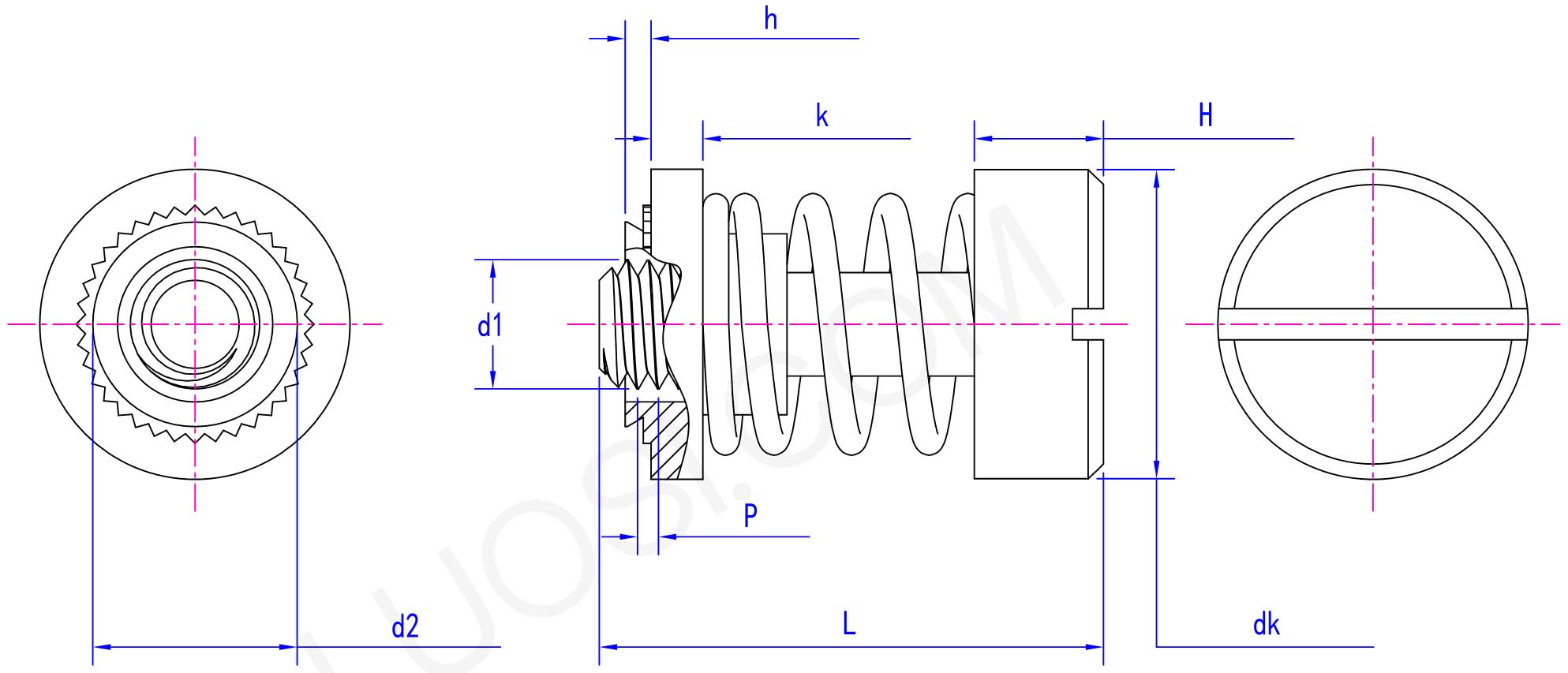

Producter parameters

| Mon | M3 | M4 | M5 | M6 |

| P | 0.5 | 0.7 | 0.8 | 1 |

| d1 | M3 | M4 | M5 | M6 |

| d2 max | 5.48 | 6.38 | 7.98 | 9.48 |

| dk max | 10.56 | 12.14 | 13.71 | 16.13 |

| dk min | 10.06 | 11.64 | 13.21 | 15.63 |

| h max | 1.48 | 1.48 | 1.48 | 1.48 |

| k max | 3.26 | 3.25 | 3.05 | 3.79 |

| k min | 3 | 2.99 | 2.79 | 3.53 |

| H max | 5.26 | 5.39 | 5.72 | 6.25 |

| H min | 5 | 5.13 | 5.46 | 5.99 |