Spring Loaded Screw

Send Inquiry

Spring loaded screw get different advanced surface treatments to work better and last longer. Common ones include electroplated zinc,sometimes with yellow, blue, or clear chromate passivation to fight rust and look better. There’s also tough Geomet® (which is like Dacromet, a zinc-flake coating), durable phosphate coatings (like manganese or zinc phosphate to hold oil and adjust friction), or fancy dry film lubricants.

Stainless Spring-Loaded Screw usually get passivated to boost their natural corrosion resistance. These treatments keep them from rusting, cut down friction when you install them (so you get more accurate clamp load), and can even give them specific electrical properties.

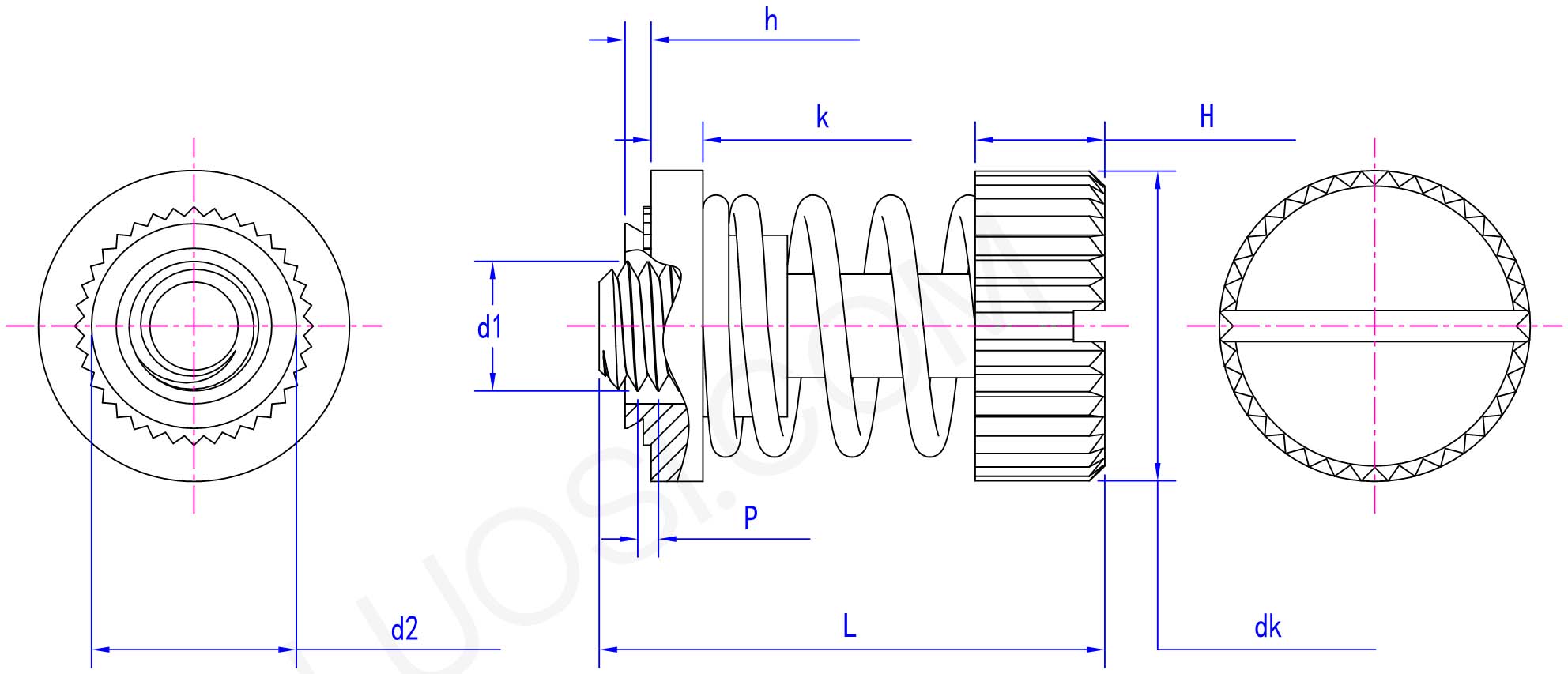

Product parameters

| Mon | 440 | 632 | 832 | 032 |

| P | 40 | 32 | 32 | 32 |

| d1 | #4 | #6 | #8 | #10 |

| d2 max | 0.202 | 0.218 | 0.249 | 0.311 |

| dk max | 0.416 | 0.448 | 0.478 | 0.54 |

| dk min | 0.396 | 0.428 | 0.458 | 0.52 |

| h max | 0.038 | 0.038 | 0.038 | 0.038 |

| k max |

0.128 |

0.128 | 0.128 | 0.12 |

| k min0.118 | 0.118 | 0.118 | 0.118 | 0.11 |

| H max | 0.207 | 0.207 | 0.212 | 0.225 |

| H min | 0.197 | 0.197 | 0.202 | 0.215 |

Size

Spring-loaded screw come in tons of sizes and types to fit different engineering needs. For metric threads, common sizes go from fine-thread M2 up to M12 or bigger. Imperial sizes range from #4 to 1/2 inch in diameter. Lengths change a lot depending on how deep they need to go in the application.

Important specs include thread pitch, head style (like hex, flange, button, or socket cap), drive type (hex socket, Phillips, Torx®), and the design of the built-in spring part (think Belleville washer, wave spring, or a specific thread shape). Most follow standards like DIN, ISO, or what OEMs require.

Quality standards and industry certifications

Q:Does it comply with international quality standards such as ISO or specific industry certifications?

A:Yep, we take production seriously. Our spring loaded screws are made to follow ISO standards,like ISO 9001 for quality control. If you need industry-specific certifications, we can do that too,things like IATF 16949 for automotive or AS9100 for aerospace. We can provide material certification reports (MTCs) and dimension checks for every batch. That way, you can track where the materials came from and make sure everything meets your project’s specs.