Split Cotter Pins

Send Inquiry

Split cotter pins are usually made from stainless steel, carbon steel, or brass,each type has its own advantages. Stainless steel ones work well in places where things might rust, since they resist corrosion and last a long time. Carbon steel cotter pins, which are often coated or galvanized, are strong and not too expensive. Brass cotter pins are good for electrical jobs because they don’t create sparks.

Picking the right material means these pins can handle extreme temperatures, chemicals, and different kinds of weight or stress. Factories make them with precise sizes and smooth surfaces, so they don’t wear down the parts they’re attached to. And because they come in different materials, they meet standard industry rules like ASTM or DIN.

Application

Split cotter pins are used all over in machines that need parts fastened semi-permanently and securely. In cars, they hold wheel bearings, brake parts, and suspension components in place. The aerospace industry uses them for control linkages and landing gear parts that need to stay put. Boats and marine stuff use cotter pins too,their rust resistance helps keep rigging and propeller shafts secure. Even DIYers use them when working on bikes, trailers, or putting furniture together.

They’re important in farm machines, construction equipment, and trains because they help prevent big, dangerous failures. Whether you’re fixing something at home or working on a huge industrial project, cotter pins make sure things stay safe and work properly.

Select size

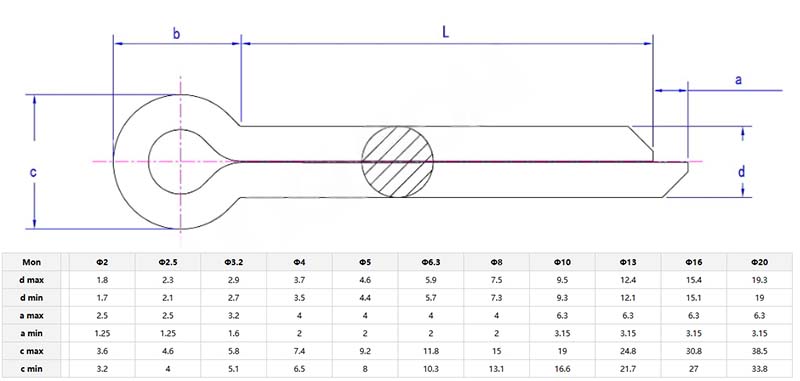

Q: How do I determine the correct size of split cotter pins for my application?

A: Picking the right cotter pin comes down to the hole’s diameter and how much weight it needs to hold. First, measure the hole where you’ll install the pin,the pin’s diameter should match the hole pretty closely. The length also matters: it needs to let both split ends stick out enough so you can bend them to lock everything in place. For instance, if the hole is 3mm wide, get a 3mm-diameter cotter pin.

Check engineering charts to see how much load the split pin can handle, or just tell your supplier what you’re using it for. Don’t go with a pin that’s too small,if it’s undersized, it might break under pressure.