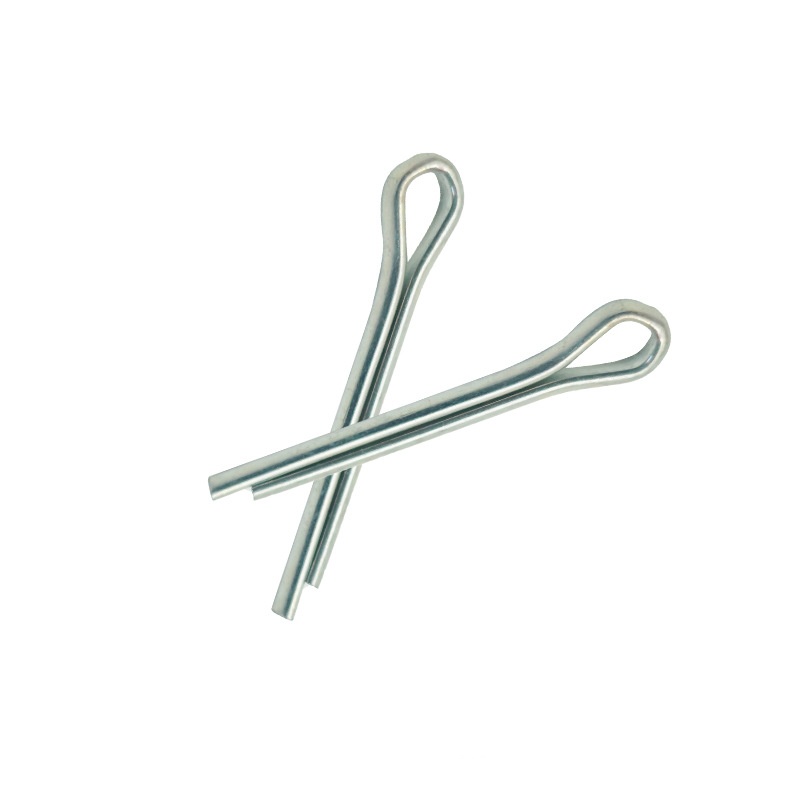

Secure Locking Split Pin

Send Inquiry

First, ensure the size of the Secure locking split pin matches the hole diameter on the bolt or shaft. If it's too small, the part won't be secured; if it's too large, it won't install at all.

Pass the cotter pin through the hole until the rounded end is locked. Then, bend the two tips in opposite directions to lock it in place. You don't need any complicated tools—just pry it open with your fingers or pliers. This way, the cotter pin won't loosen even if the secured object shakes.

To remove the split pin, straighten the bent tips with pliers and pull it out. It's best to use a new cotter pin each time you reassemble, as old cotter pins weaken after repeated bending.

Our Secure locking split pin come in simple, practical packaging with no fancy designs. We pack them in plastic bags or small cardboard boxes to prevent them from bending or rusting during shipping.The label on the packaging contains all the information you need: size, material, and quantity. This way, you can easily find the cotter pin you need without having to open every package.

For larger orders, we use large packaging boxes with dividers. These dividers can separate cotter pins of different sizes, preventing them from getting tangled. The packaging is compact and lightweight, and won't take up much space in your toolbox or on your shelves.

We insist on simple packaging—no unnecessary layers or decorations—which helps reduce costs.Whether you're buying a few wire cutters for home use or a large quantity for work, this packaging ensures your wire cutters arrive intact and ready to use.

Question: What materials are your Secure Locking split pin made from?

Answer: Our standard products are made from low-carbon steel—good for regular, everyday use. We’ve also got stainless steel ones (A2-304 and A4-316) that hold up better against rust and corrosion. And if you need non-magnetic split pins, we have brass ones too. These cover different environmental needs, so you can pick whatever works for what you’re doing.

| d | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3.2 | 4 | 5 | 6.3 | 8 | 10 | 13 | 16 | 20 | |

| d | max | 0.5 | 0.7 | 0.9 | 1 | 1.4 | 1.8 | 2.3 | 2.9 | 3.7 | 4.6 | 5.9 | 7.5 | 9.5 | 12.4 | 15.4 | 19.3 |

| min | 0.4 | 0.6 | 0.8 | 0.9 | 1.3 | 1.7 | 2.1 | 2.7 | 3.5 | 4.4 | 5.7 | 7.3 | 9.3 | 12.1 | 15.1 | 19 | |

| a | max | 1.6 | 1.6 | 1.6 | 2.5 | 2.5 | 2.5 | 2.5 | 3.2 | 4 | 4 | 4 | 4 | 6.3 | 6.3 | 6.3 | 6.3 |

| min | 0.8 | 0.8 | 0.8 | 1.25 | 1.25 | 1.25 | 1.25 | 1.6 | 2 | 2 | 2 | 2 | 3.15 | 3.15 | 3.15 | 3.15 | |

| b≈ | 2 | 2.4 | 3 | 3 | 3.2 | 4 | 5 | 6.4 | 8 | 10 | 12.6 | 16 | 20 | 26 | 32 | 40 | |

| C | max | 1 | 1.4 | 1.8 | 2 | 2.8 | 3.6 | 4.6 | 5.8 | 7.4 | 9.2 | 11.8 | 15 | 19 | 24.8 | 30.8 | 38.5 |

| min | 0.9 | 1.2 | 1.6 | 1.7 | 2.4 | 3.2 | 4 | 5.1 | 6.5 | 8 | 10.3 | 13.1 | 16.6 | 21.7 | 27 | 33.8 | |