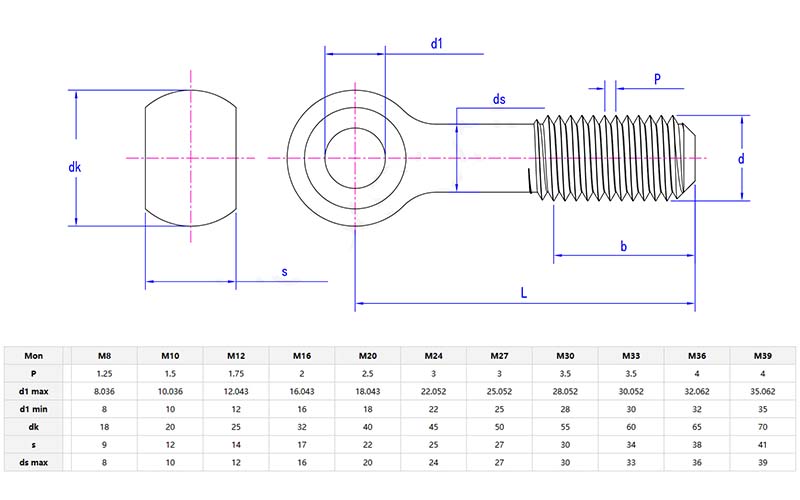

Slipknot Bolt

Send Inquiry

Slipknot Bolts are made from good-quality materials like stainless steel, carbon steel, or titanium alloys that makes the bolt strong and resistant to rust. Stainless steel bolts work great in damp or rusty environments. Carbon steel that has been heat-treated can handle heavy loads, that is good for big machines. Titanium bolts are light but still high strength, which are perfect for airplanes or cars.

Depending on the different usage environments, different materials are selected to make bolts, which can remain in good condition for a long time and be reused repeatedly. So, they can be used in both industrial machines and daily consumer products.

Product details

Slipknot Bolts are super handy in jobs where you need things to move just right. In cars, they keep wheels aligned properly. For conveyor belts, they let you adjust the belt if it slips out of place. Engineers use it to fine-tune the joints of the robot.

Among furniture products, it is convenient to adjust the slope. For heavy machinery, it can stabilize the mechanical arms. In the photovoltaic industry, workers often use it to adjust the Angle of solar panels to obtain more sunlight.

Whether you’re fixing stuff at home or building something huge, these bolts makes our work easier, sets up gear smoothly and adapts to whatever you’re doing.

Q&A

Q: Can the Slipknot Bolt be installed without specialized tools?

A: That’s pretty straightforward to work with. They’ve got standard wrench slots or hex heads, so you can just use regular tools like a wrench or Allen key. There are clear specs on how much to tighten them, so you won’t crank them too hard and mess things up. Some even include locking nuts or thread glue to stop them from wiggling loose over time. If you’re stuck, the manual or online guides break it down—no guesswork. Just check the manual or hit up the online tutorials—they’ll show you exactly what to do, step by step.