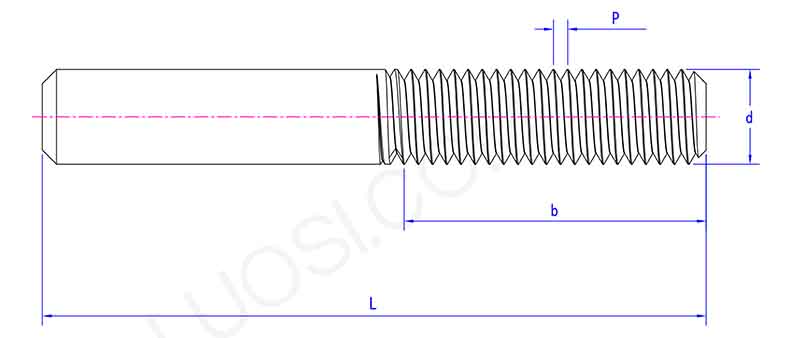

Single Head Threaded Studs

Send Inquiry

Single head threaded studs are metal rod with threads. One end is the welding head, and the other end has threads that can be used to tighten nuts. The head may be flat, round, or have several small protrusions, which are designed to facilitate positioning during welding.

Product feature

Using single head threaded studs results in a much stronger connection. It's much more reliable than using screws. Even if you pull hard, it won't come off easily. When welding, there is no need to drill holes on the workpiece. Just place the stud on it and it can be welded. This method causes little damage to the workpiece. Moreover, it is fast and highly efficient during mass production, and no overly complex equipment is required.

Product applications

|

Mon |

M6 | M8 | M10 | M12 | M16 | M20 | M24 | M30 | M36 | M42 | M48 |

|

P |

1 | 1.25 |

1.5 |

1.75 |

2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 |

Auto repair shops often use single end threaded studs. When the screw holes on the car doors are damaged, they weld studs to serve as new fixing points; when the brackets on the chassis are broken, they weld studs to reinstall the brackets. During the repair process, there is no need to replace the entire panel, which saves money and is quick. The owner can pick up the car on the same day without being affected by the inconvenience of not being able to use it normally.

Single end threaded studs are used in agricultural machinery repair. In rural areas, when repairing agricultural machinery such as tractor buckets and harvesters' frames, these parts are relied upon to provide emergency solutions when others are broken. The cargo box cover fell off. Just weld a screw and reattach it. The hook on the frame broke. Weld a screw and use it as a new hook.

Making pet cages and tool boxes, and the single head threaded studs are very useful. At the intersection of the bars of the cage, weld a screw column and tighten it. This is more sturdy than spot welding. Even if the pet bites or the tools collide, it won't be damaged. To add a partition, just weld several screw columns on the cage.