Single Head Threaded Stud

Send Inquiry

Single head threaded stud is a metal rod. One end has threads for easy screwing of nuts, and the other end is the welding end, which has flat surfaces and small raised parts. There are various sizes of threads, which can be matched with different thicknesses.

Product Advantages

Single end threaded studs are connected using standard welding rods and welding machines. Simply fix the studs in place, create an arc between them and the base material, and then fuse them together. No special equipment is required; all you need is to master the welding skills and have basic equipment.

Using single head threaded stud can achieve permanent fixation. Fix the M6 screws inside the equipment frame. Install the bolt protection device, and the threads will not come off. No need to retighten for OSHA inspection. They can reinforce the joints. Use any arc welding machine to fix the M8 screws at the beam connection points. Add plates and nuts. It won't shake under heavy load. No need to disassemble.

Check your hand-welded joints: The high-quality threaded stud should ensure complete fusion at the bottom. Hit them with a hammer and a clear 'clink' indicates a secure weld. If the sound is dull, scrape off the weld slag and re-weld the weak area. They can be used for low-carbon steel, stainless steel, and even cast iron (preheated).

Product Features

The feature of the single head threaded stud is that the welding ends are relatively simple to handle and easy to align manually. The metal rods have a moderate hardness, making them less likely to break during welding and less brittle after cooling. The threaded part is well-designed, and there is no jamming when tightening the nut.

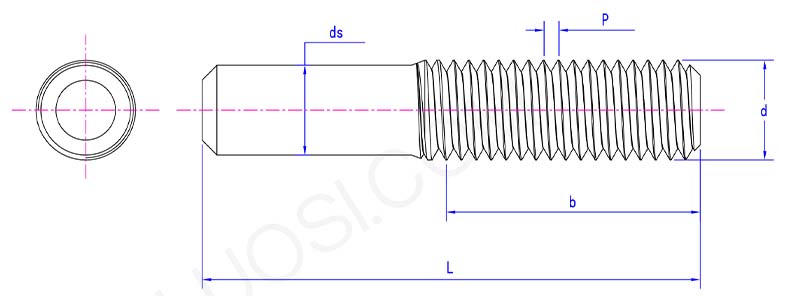

Product Parameters

|

Mon |

M6 | M8 | M10 | M12 | M14 | M16 |

|

P |

1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

|

ds |

5.35 |

7.19 |

9.03 | 10.86 | 12.70 | 14.70 |