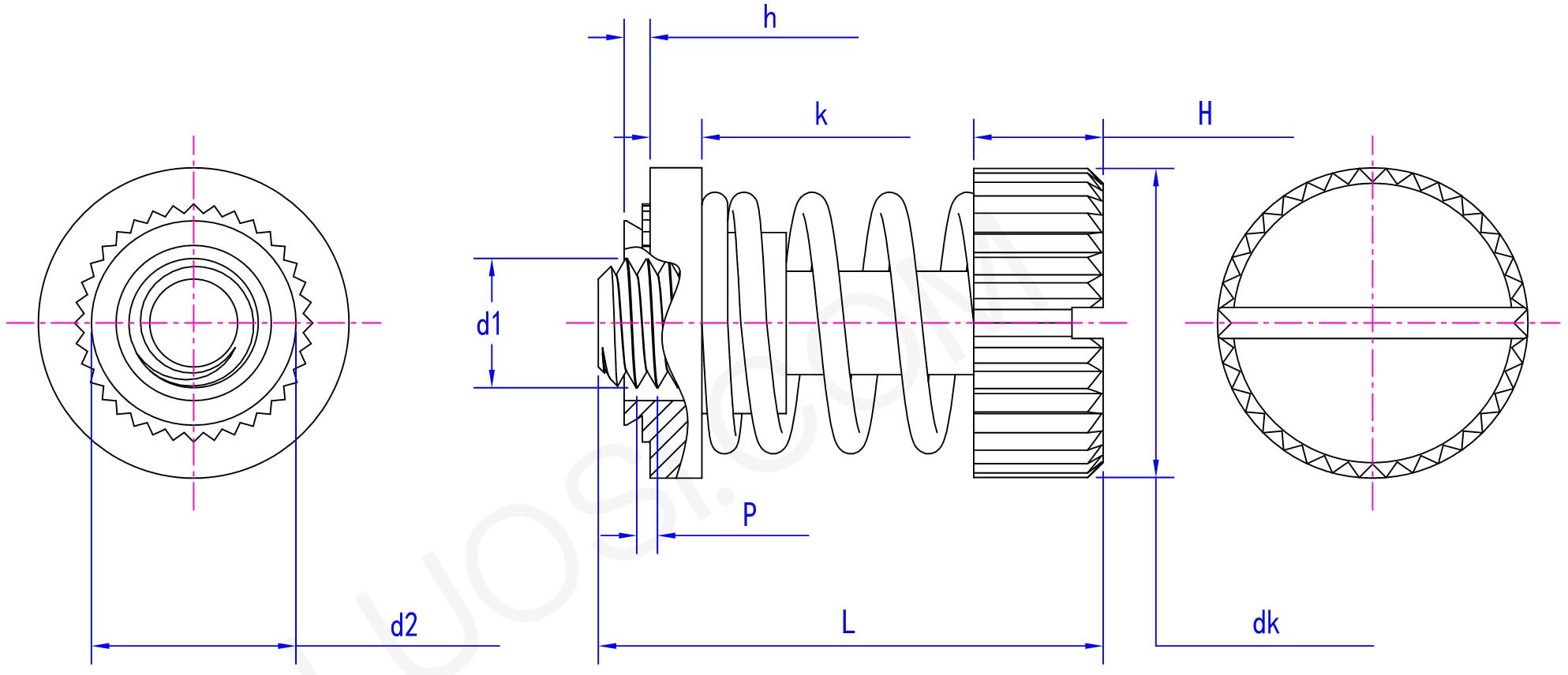

Self Retaining Screw

Send Inquiry

Self retaining screws can be made of a variety of materials, depending on the specific needs and applications.The alloy steel types is mostly iron and carbon, with some extra bits like chromium and molybdenum thrown in ,sometimes vanadium or nickel too. Once we heat-treat them, they get seriously strong, hitting tensile strengths up around 1600 MPa. The stainless steel versions use iron-chromium-nickel mixes (like common grades 304 or 316). These fight off rust really well, but honestly, they aren't quite as tough as the hardened alloy steel.

Regular inspection and maintenance

Keeping self retaining screw working well is mostly about giving them a quick look now and then. Check for rust, any dings or bends, or if the spring’s getting weak (though that’s pretty rare). If you picked the correct ones and put them in right to start with, they usually don’t need much fuss,they’re built to stay tight on their own.

If you do take them out,be gentle,don’t mess up the screw head or the spring part. When putting them back, just grab new Self-Retaining Screws instead of reusing the old ones. Reused ones often won’t grip as well. Oh, and keep things clean,wipe off heavy dirt or corrosive gunk,helps them last way longer.

Product parameters

| Mon | M3 | M4 | M5 |

| P | 0.5 | 0.7 | 0.8 |

| dk max | 10.56 | 12.14 | 13.71 |

| dk min | 10.06 | 11.64 | 13.21 |

| h max | 0.97 | 0.97 | 0.97 |

| d2 max | 5.48 | 6.38 | 7.98 |

| d1 | M3 | M4 | M5 |

| k max | 3.26 | 3.25 | 3.05 |

| k min | 3 | 2.99 | 2.79 |

| H max | 5.26 | 5.39 | 5.72 |

| H min | 5 | 5.13 | 5.46 |

MOQ

Q: What is your typical minimum order quantity (MOQ) , and how does pricing scale?

A: Our regular minimum order is about 10,000 pieces. But if you just need samples or prototypes? We can usually do smaller batches for those.

Price drops significantly when you order more,bigger runs cut production costs. We do bulk discounts, so just tell us roughly how many you need. We’ll then send you a sharp quote matching your quantity.