Secure Split Pins

Send Inquiry

Secure Split Pins—people also call them cotter pins or split cotters—are basic fasteners mainly used to hold parts in place on shafts, axles, or in clevis pins and castle nuts. They’re split, which lets the two legs bend back once you push them through a hole. That creates a solid mechanical lock. This stops nuts from loosening, pins from sliding out, or linkages from coming apart when there’s vibration or spinning forces. It keeps important assemblies safe and together even when things get tough. Their main job is to hold things securely, and they don’t cost much.

Product Details

Secure Split Pins get used in a ton of different places. You need them for car suspensions—holding ball joints and tie rods in place—farm machine parts that link together, industrial valve setups, bike wheel axles, airplane control systems, and marine hardware. Any joint that spins or swivels, where vibration might make it come apart or it could accidentally disconnect, is a good spot for a split pin. They’re simple, so you can put them in fast and check at a glance if they’re holding things tight. That’s why they’re used everywhere in mechanical and structural work when you need a reliable, removable way to keep things locked safely.

| Mon | Φ2 |

Φ3.2 |

Φ4 |

Φ5 |

Φ6.3 |

Φ8 |

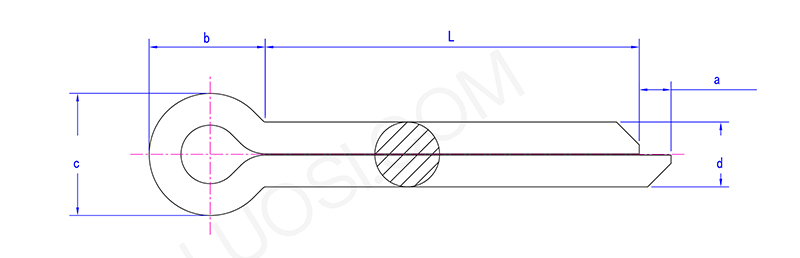

| d max | 1.8 | 2.9 | 3.7 | 4.6 | 5.9 | 7.5 |

| d min | 1.7 | 2.7 | 3.5 | 4.4 | 5.7 | 7.3 |

| c max | 3.6 | 5.8 | 7.4 | 9.2 | 11.8 | 15 |

| c min | 3.2 | 5.1 | 6.5 | 8 | 10.3 | 13.1 |

| a max | 2.5 | 3.2 | 4 | 4 | 4 | 4 |

FAQ

Q:What materials are your Secure Split Pins typically made from?

A:Most of our Secure Split Pins are made from carbon steel—usually with a zinc plating to keep them from rusting—or stainless steel (A2/A4 grades). The choice of material depends entirely on your work requirements, including the actual use environment of the material, the required strength standards, and your budget. We make sure all our Secure Split pins meet the right international material standards, so they work consistently and hold up even when conditions are tough.