Projection Weld Studs

Send Inquiry

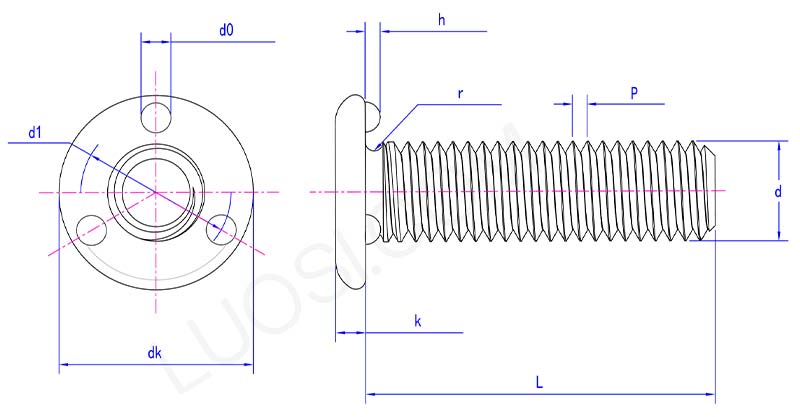

The projection weld studs are mainly composed of a screw and a head with a special raised structure. They can be combined with nuts or other components with internal threads. These protrusions can be composed of multiple small cylindrical, ring-shaped or other specific forms.

Features and applications

The unique protrusions on the head of the weld stud with 3 projections under the head enable precise current concentration during welding, ensuring a stable and reliable welding process and significantly guaranteeing the welding quality. Due to the concentrated force on the protrusions, the thermal impact on other parts of the weldment during welding is relatively small, which can well maintain the original performance and appearance of the weldment and will not cause excessive deformation or damage due to welding.

The projection weld studs are both easy to weld and very strong. The current is concentrated in the protruding part of the head, quickly connecting the stud to the workpiece. This method is much more efficient than the ordinary welding method. It has its own positioning function. During installation, no complex positioning operations are required. It can automatically find the correct position, significantly saving installation time.

Projection underweld screws are used for assembling the shells of electronic devices. For instance, in the assembly of products such as computer mainframes, mobile phone casings, and tablet computer casings, they play a crucial role. When installing the components such as the hard drive bracket, power supply fixing frame, and fan support inside the mainframe case, first attach them to the corresponding positions on the case shell, and then fix these accessories by using the threads on the screws.

Projection weld studs are used in the construction of building steel structures. For structures such as factories, warehouses, stadiums, bridges, etc., they are often used at the connection nodes between steel beams and steel columns. First, the studs are welded to the ends of the steel beams or steel columns, and then the steel beams and steel columns are fastened together through bolts or other connecting components.

Product parameters

|

Mon |

M4 | M5 | M6 | M8 | M10 | M12 |

|

P |

0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

|

dk max |

10.4 | 12.4 | 14.4 | 18.4 | 22.4 | 26.4 |

|

dk min |

9.6 | 11.6 | 13.6 | 17.6 | 21.6 | 25.6 |

|

k max |

1.5 | 2 | 2.2 | 2.7 | 3.7 | 4.7 |

|

k min |

1.1 | 1.6 | 1.8 | 2.3 | 3.3 | 4.3 |

|

r max |

0.5 | 0.6 | 0.7 | 0.9 | 1.2 | 1.4 |

|

r min |

0.2 | 0.2 | 0.25 | 0.4 | 0.4 | 0.6 |

|

d0 max |

1.75 | 2.25 | 2.75 | 3.25 | 4.25 | 4.25 |

|

d0 min |

1.25 | 1.75 | 2.25 | 2.75 | 3.75 | 3.75 |

|

h max |

0.8 | 0.8 | 0.9 | 0.9 | 1.1 | 1.1 |

|

h min |

0.6 | 0.6 | 0.7 | 0.7 | 0.9 | 0.9 |

|

d1 |

8.5 | 10 | 11.5 | 15 | 18 | 21 |