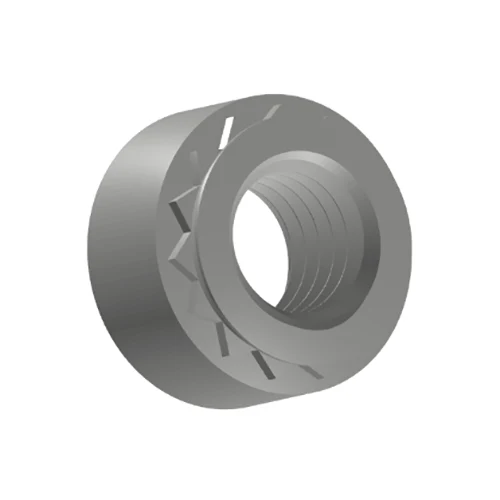

China Hexagon nut for transmission tower anchor Manufacturer, Supplier, Factory

Transmission tower anchors are critical components in ensuring the stability and longevity of power line infrastructure. To meet the demanding requirements of these applications, our hexagon nut for transmission tower anchor is engineered with precision and durability in mind. This product is designed to withstand extreme environmental conditions, including high winds, temperature fluctuations, and corrosive elements, providing a reliable fastening solution for anchor systems. For specialized needs, we also offer related products such as Hexagon Extra Flat Nuts With Fine Pitch Thread, which offer enhanced thread engagement for fine adjustments, and Inch Hexagon Thick Nuts With Washer Faced, ideal for applications requiring additional bearing surface. Additionally, our Hexagon Nut For Pressure Vessel Flange and High Pressure Hexagon Nuts cater to high-stress environments, ensuring safety and performance across various industrial uses. Each product is manufactured to meet international standards, with a focus on reliability and ease of installation.

The Hexagon nut for transmission tower anchor is crafted from high-grade materials, such as carbon steel or stainless steel, to provide superior tensile strength and corrosion resistance. Key parameters include precise thread dimensions, which ensure compatibility with standard bolts used in tower anchoring systems. Below is a detailed overview of the product specifications:

- Material: Carbon Steel (Grade 8.8 or higher) or Stainless Steel (A4-80)

- Surface Treatment: Hot-dip galvanized or zinc-plated for enhanced durability

- Thread Type: Metric coarse or fine pitch, conforming to ISO 898-2 standards

- Operating Temperature Range: -50°C to +300°C, suitable for diverse climates

- Load Capacity: Designed to handle dynamic loads up to 100 kN without deformation

For a comprehensive view, refer to the table below that outlines standard sizes and dimensions:

| Size (M) | Width Across Flats (mm) | Height (mm) | Thread Pitch (mm) | Proof Load (kN) |

|---|---|---|---|---|

| M16 | 24 | 16 | 2.0 | 70 |

| M20 | 30 | 20 | 2.5 | 90 |

| M24 | 36 | 24 | 3.0 | 110 |

| M30 | 46 | 30 | 3.5 | 140 |

These specifications ensure that the Hexagon nut for transmission tower anchor delivers optimal performance in securing transmission towers, minimizing maintenance needs and enhancing overall system integrity. Regular quality checks and adherence to industry standards guarantee consistency and reliability in every batch.

Hot Products

80°Slotted Countersunk raised head screws truncated

Xiaoguo® manufactures 80°Slotted Countersunk raised head screws truncated to BS 1981-10-1991. These 80°Slotted Countersunk raised head screws truncated have a raised edge when laid flat, which increases the grip and are used in industries such as electronics and automotive.Hexagon flange bolts Types U

Hexagon flange bolts Types U has a large contact surface for connecting components and good friction, which better fixes the equipment. We can provide you quotation, so you can contact Xiaoguo® in China at any time for inquiries. If you are satisfied with the price, we can arrange it for you immediately and send you free samples for testing at the same time.High Efficiency Weld Studs

The manufacturers Xiaoguo® offers a diverse range of products like screws and bolts.The primary function of high efficiency weld studs is to provide a robust, permanently attached threaded or unthreaded stud protruding from a surface.Metal Dual Hook Tension Spring

Metal Dual Hook Tension Spring, as a key product from the supplier Xiaoguo®, is designed by its engineering team with precise initial tension and hook configurations. The initial tension built into it is a critical characteristic, meaning a certain force must be applied before the coils even begin to separate.Metric Hexagon Head Anchor Bolt

Metric hexagon head anchor bolts can be used to secure structural steel beams and columns. They are used in power plant installations and can also be used in industrial plants for structural support. Xiaoguo® has sufficient inventory in the factory and can be ordered in bulk.UN Clinching Nut-Aluminium Alloy

Baoding Xiaoguo Intelligent Equipment Co., LTD. is UN clinching nut-Aluminium alloy manufacturer and supplier in China who can wholesale UN clinching nut-Aluminium alloy. We can provide professional service and better price for you. If you interested in UN clinching nut-Aluminium alloy products, please contact with us. We follow the quality of rest assured that the price of conscience, dedicated service.