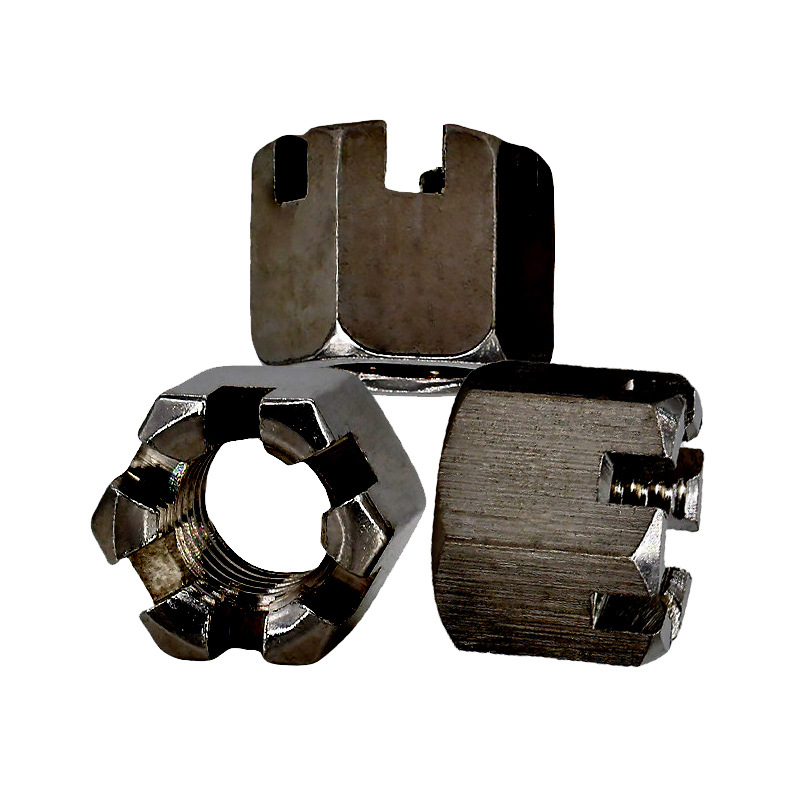

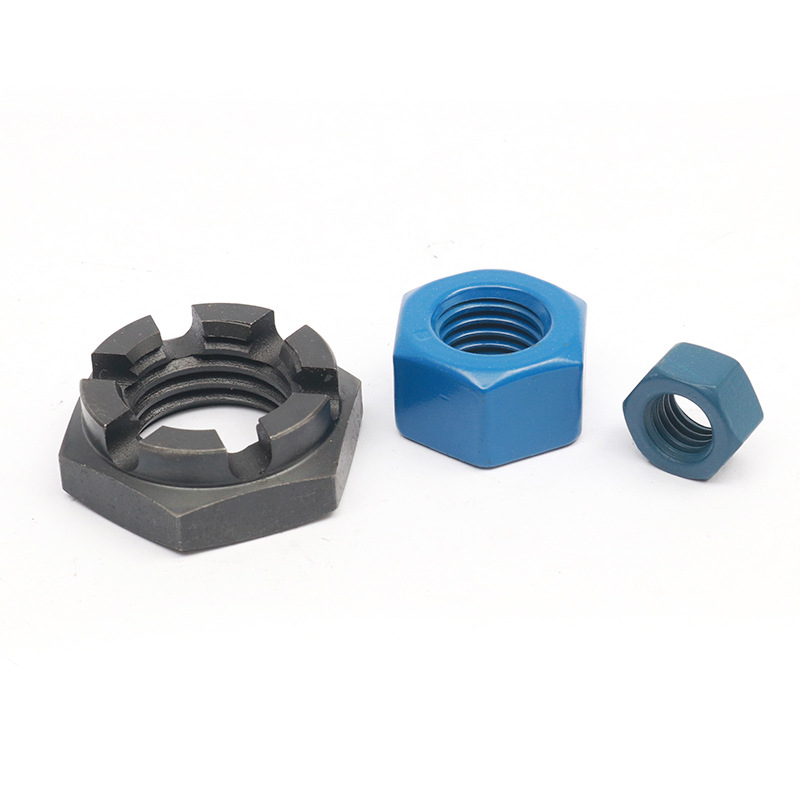

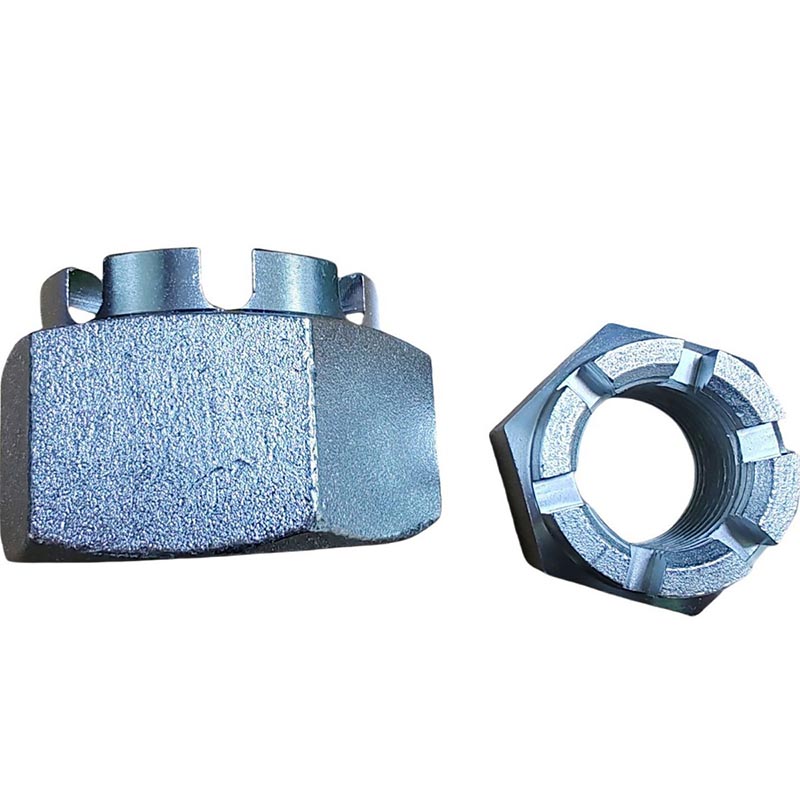

Precision Machined Crown Nut With Slot

Send Inquiry

Precision-machined Crown nut with slot are usually made from strong carbon steel or alloy steel—like Grade 5, Grade 8, or AISI 4140. This property gives them excellent toughness, and they also perform well in the three key mechanical properties of tensile strength, yield strength and shear strength. Being made of strong steel means these nuts can handle a lot of clamping force and stress from use without bending or breaking. That’s why they work well for heavy-load jobs in tough places—like structural frames, drivetrains, and suspension parts.

Excellent anti-corrosion performance

If the Precision-machined Crown nut with slot are going to be used in places where rust or chemicals are a problem—like on boats, in chemical plants, or in food factories—they’re often made from austenitic stainless steel, such as A2/304 or A4/316. Sometimes they use corrosion-resistant alloys like Inconel or Monel too. These materials have excellent resistance to rust and oxidation, and are also highly resistant to a wide range of chemicals. Even in extremely harsh environments (such as strong impact, corrosive media, high and low temperature cycles), this nut can still maintain excellent firmness, and its locking performance is stable and reliable and not easy to loosen. They don’t get stuck, and it’s easier to maintain them over time.

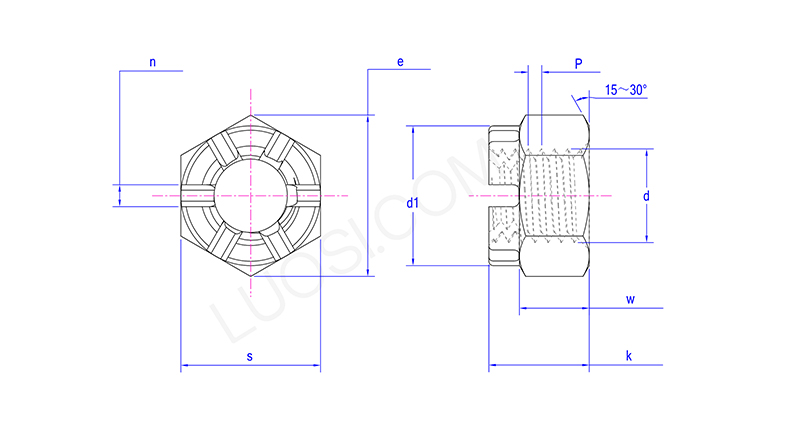

| Mon | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 |

| P | 1.5 | 1.5|2 | 1.5 | 2 | 2 | 2 | 2 | 3 |

| d1 max | 25 | 28 | 30 | 34 | 38 | 42 | 46 | 50 |

| d1 min | 24.16 | 27.16 | 29.16 | 33 | 37 | 41 | 45 | 49 |

| e min | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 |

| k max | 21.8 | 24 | 27.4 | 29.5 | 31.8 | 34.6 | 37.7 | 40 |

| k min | 20.96 | 23.16 | 26.56 | 28.66 | 30.8 | 33.6 | 36.7 | 39 |

| n max | 5.7 | 5.7 | 6.7 | 6.7 | 6.7 | 8.5 | 8.5 | 8.5 |

| n min | 4.5 | 4.5 | 5.5 | 5.5 | 5.5 | 7 | 7 | 7 |

| s max | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 |

| s min | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 |

| w max | 15.8 | 18 | 19.4 | 21.5 | 23.8 | 25.6 | 28.7 | 31 |

| w min | 15.1 | 17.3 | 18.56 | 20.66 | 22.96 | 24.76 | 27.86 | 30 |

FAQ

Q:What surface treatments or coatings are offered to enhance corrosion resistance for the Precision-machined Crown nut with slot?

A:We offer different surface treatments to keep Precision-machined Crown nut with slot from rusting during shipping and in tough environments. Common choices are zinc plating (clear, blue, or yellow chromate—minimum 5μm Fe/Zn), hot-dip galvanizing (HDG), Geomet (zinc-flake coating), or Dacromet. For stainless steel ones, passivation is standard. Just let us know how much corrosion protection you need for the slotted crown nuts, depending on where they’ll be used.