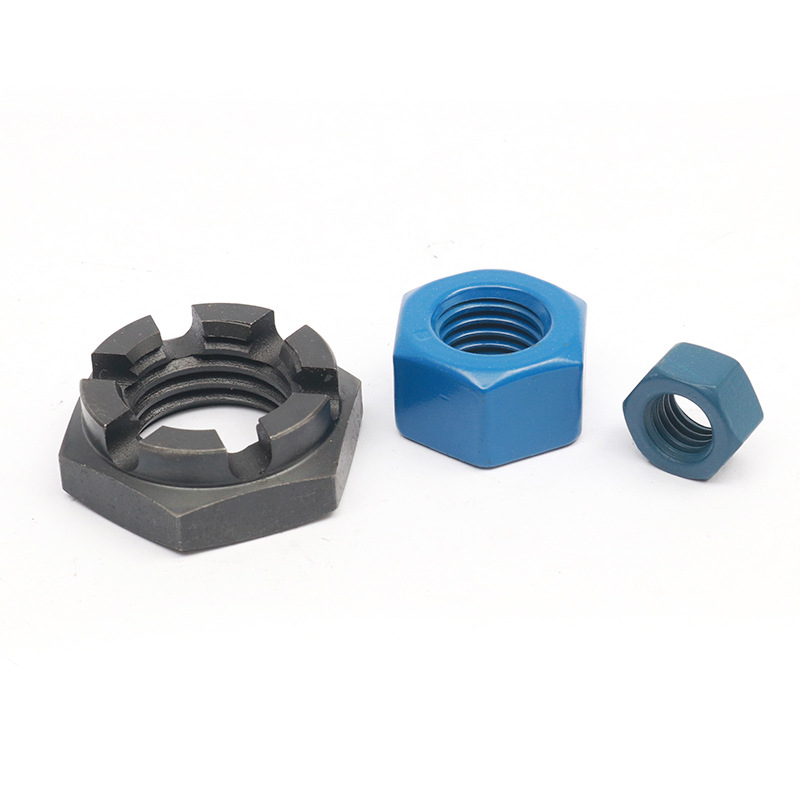

Positively Locking Crown Nut With Slot

Send Inquiry

This Positively Locking Crown Nut With Slot is widely used in heavy industrial equipment, such as presses, conveying systems and rotating shafts, etc.

In those machines where even the slightest gap or nut loosening could lead to serious failures, this slotted round head nut provides a reliable mechanical locking method. People especially like it because it is easy to install and inspect. Maintenance personnel can quickly confirm the firmness of the connection by simply checking the locking pin. That's why it is the preferred material in those safety-critical tasks in manufacturing factories.

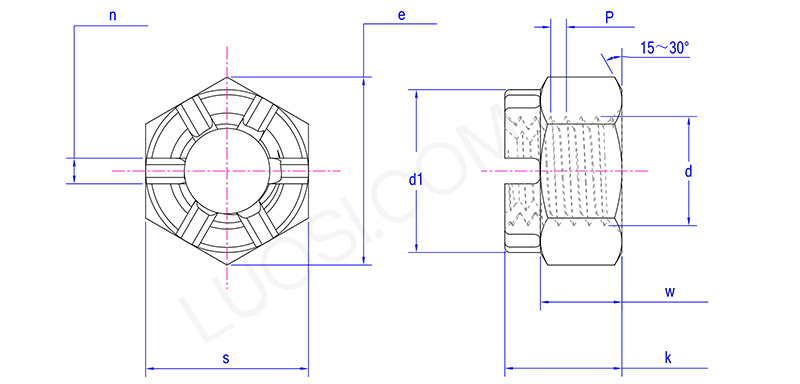

Product Parameters

| Mon | M20 | M24 | M30 | M36 |

| P | 1.5|2|2.5 |

1.5|2|3 |

1.5|2|3.5 |

1.5|2|3|4 |

| d1 max | 28 | 34 | 42 | 50 |

| d1 min | 27.16 | 33 | 41 | 49 |

| e min | 32.95 | 39.55 | 50.85 | 60.79 |

| k max | 26.3 | 31.9 | 37.6 | 43.7 |

| k min | 25.46 | 31.06 | 36.7 | 42.7 |

| n min | 4.5 | 5.5 | 7 | 7 |

| n max | 5.7 | 6.7 | 8.5 | 8.5 |

| s max | 30 | 36 | 45 | 55 |

| s min | 29.16 | 35 | 45 | 53.8 |

| w max | 20.3 | 23.9 | 28.6 | 34.7 |

| w min | 19 | 22.6 | 27.3 | 33.1 |

Excellent rust resistance

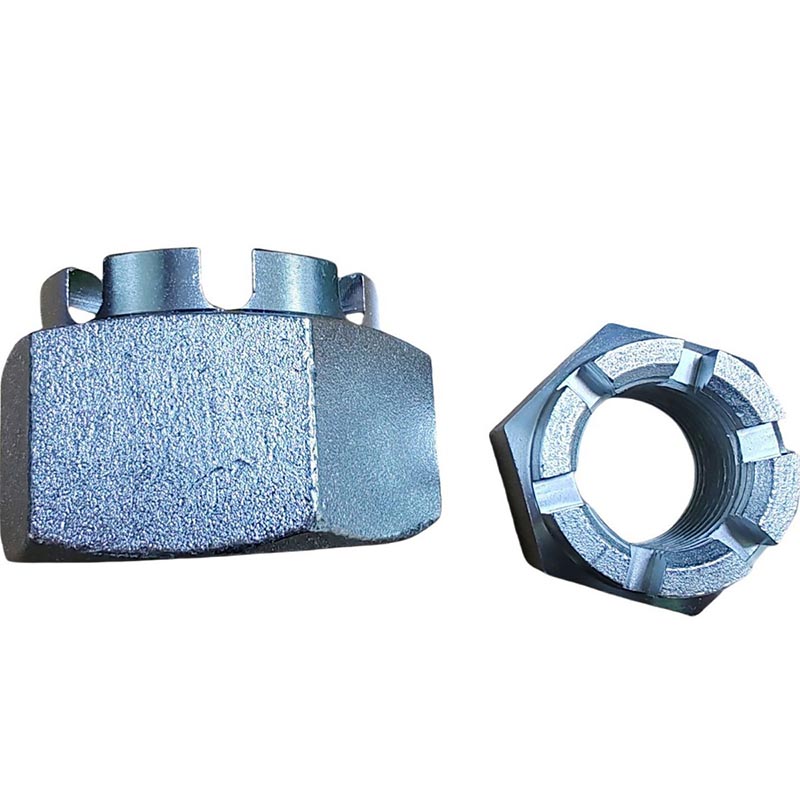

In ships and offshore facilities, Positively Locking Crown Nut With Slot are used for lifting, deck machinery, and structural connections. They are usually made of stainless steel or other non-corrosive materials, thus being able to withstand the harsh environment of seawater.

Here, the method of locking with the split pin is very important - the equipment must be able to withstand continuous movement caused by waves and wind. This ensures that the important connections on ships and offshore platforms are stable, thereby ensuring safety and enabling the equipment to operate normally.

FAQ

Q:What materials are your crown nuts with slots available in?

A:Our Positively Locking Crown Nut With Slot come in different materials—so they can fit different environmental needs and strength requirements. When choosing materials, we usually choose grade 8 steel and stainless steel (such as SS304 or SS316). Brass is also very commonly used.

You need to consider how much force you want it to withstand (that is, it shouldn't break easily when you pull it), whether it is rust-proof (after all, if it rusts easily, it will break after a short period of use), and whether it is compatible with the other materials you use for assembly (if you put two materials together, problems will occur). If you’re not sure, we can help you figure out the best material for your specific use.