Open Type End Blind Rivets

Send Inquiry

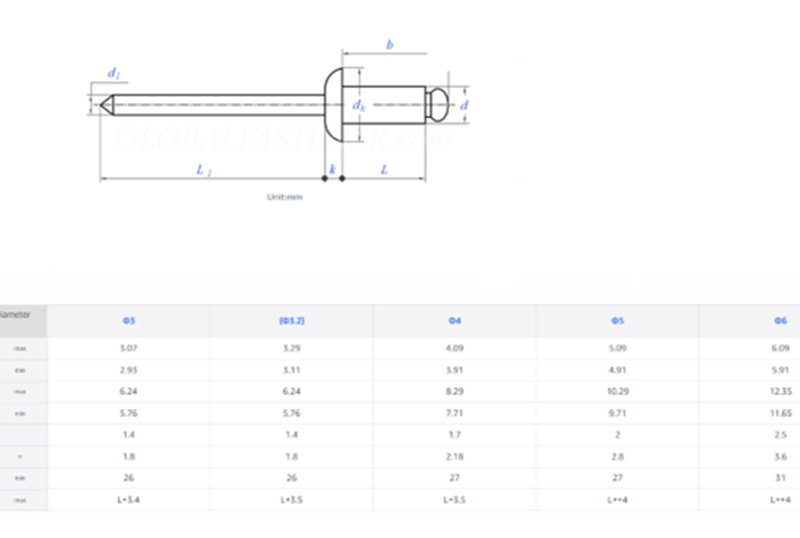

Open type end blind rivets are a type of riveted joint and a fastening connector with a countersunk head design that is flush with the mounting surface for aesthetics and to minimize obstruction. Open type end blind rivets are installed with a special tool, and the core is pulled to expand the rivet and tighten it. It is suitable for thin plate connection, which is widely used in many fields such as automobile, aviation, electronic equipment manufacturing, etc., the connection is firm and efficient.

Blind rivets classification

GB/T12615 Closed end blind rivets with break pull mandrel and flat round head;

GB/T12616 Closed end blind rivets with break pull mandrel and countersunk head;

GB/T 12617 open type end blind rivets with break pull mandrel and countersunk head;

GB/T 12618 open type end blind rivet with break pull mandrel and flat round head

Advantages

Open type end blind rivets have a wide riveting range, quick installation, stable and reliable performance, and are used in processing and manufacturing industries around the world.

Open type end blind rivets with the help of a special rivet gun, a single person can quickly complete the riveting operation, significantly reducing installation time and improving work efficiency.

Working principle

The riveting of open type end blind rivets is the use of a slightly smaller diameter than the perforation of the metal cylinder goods metal tube (rivet), through the need to rivet the work piece, and the rivets on both sides of the face of the hammer or pressure, so that the metal column (tube) deformation and thickening of the colleagues in the formation of the ends of the riveting head (cap), so that the work piece can not be disengaged from the rivets, in the case of the separation of work piece by the external force is the role of the nail rod, the cap of the nails to withstand the resulting shear force, to prevent the separation of the work piece.

Installation steps

Firstly, according to the rivet diameter and plate thickness, machine suitable rivet holes in the connected parts.

Insert open type end blind rivets into the holes, making sure that the countersunk head portion fits the surface of the part being joined.

Clamp the mandrel of the rivet using a special rivet pulling gun and pull the handle of the gun so that the mandrel is stretched.

As the mandrel stretches, the body of the open type end blind rivets expands and forms a tight joint until the mandrel is pulled off and the installation is complete.