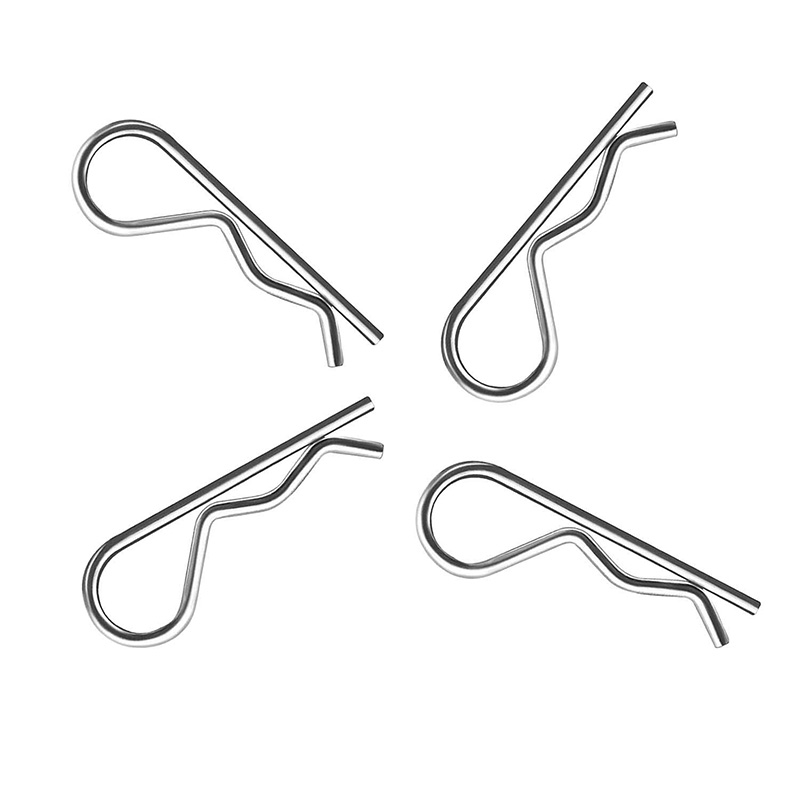

Locking Cotter Pin

Send Inquiry

In the process of car manufacturing, Locking Cotter Pins are used to fix components during the assembly of the car or when conducting tests on it. They have a quick-release function - allowing the production line to operate more quickly while ensuring the components are securely fixed. These colored lock pins are easy to observe, which helps operators avoid errors when fastening the parts.

Product Details

For the aerospace industry, the Locking Cotter Pins must be extremely reliable - as the components they secure are of vital importance. These locking pins are made of special alloys, enabling them to withstand significant pressure and temperature variations. They also undergo additional tests, such as X-ray inspections and fatigue tests, to meet the safety standards of the aerospace sector.

| Mon |

Φ4 |

Φ5 |

Φ6 |

Φ8 |

Φ10 |

Φ12 |

Φ14 |

Φ16 |

| d1 | 1 | 1 | 1.2 | 1.6 | 1.8 | 1.8 | 2 | 2 |

| L | 16.3 | 17.9 | 21.2 | 27.7 | 32.6 | 35.8 | 40.6 | 43.8 |

| d2 | 3 | 3 | 3.6 | 4.8 | 5.4 | 5.4 | 6 | 6 |

| L1 | 6 | 6.5 | 7.8 | 10.4 | 12.2 | 13.2 | 15 | 16 |

| L2 | 1 | 1.5 | 1.8 | 2.4 | 2.7 | 2.7 | 3 | 3 |

Packaging Method

We’re careful about how we pack Locking Cotter Pins so they show up in good shape—even when they’re going somewhere far, like China to Europe.

First, we wrap them in strong plastic bags or small boxes so they don’t scratch or rub against each other. Then, we pack those into bigger cardboard boxes that are thick enough to handle bumps. We also add foam or dividers inside to keep everything separated and secure—that way nothing bends or breaks while it’s moving.

If the order is going somewhere humid or rainy, we slip in a plastic layer to block moisture and prevent rust. We always tape the boxes well so they stay closed.

We’ve sent out thousands of orders like this, and hardly any get damaged—less than half a percent. So you can expect your lock pins to arrive ready to use.