Knurled Head Spring Screws

Send Inquiry

To enhance the rust resistance and aesthetic appeal of knurled head spring screws, they are typically finished with various surface coatings. Common coatings include zinc plating (transparent, yellow or black chromate), electroless nickel plating, Geomet (zinc flake) coating, and stainless steel passivation.

When picking a coating, it needs to work with both the screw material and the knurled design. The coating can’t stop the knurled part from biting into the material, and it shouldn’t mess with how the spring washer works once it’s applied.

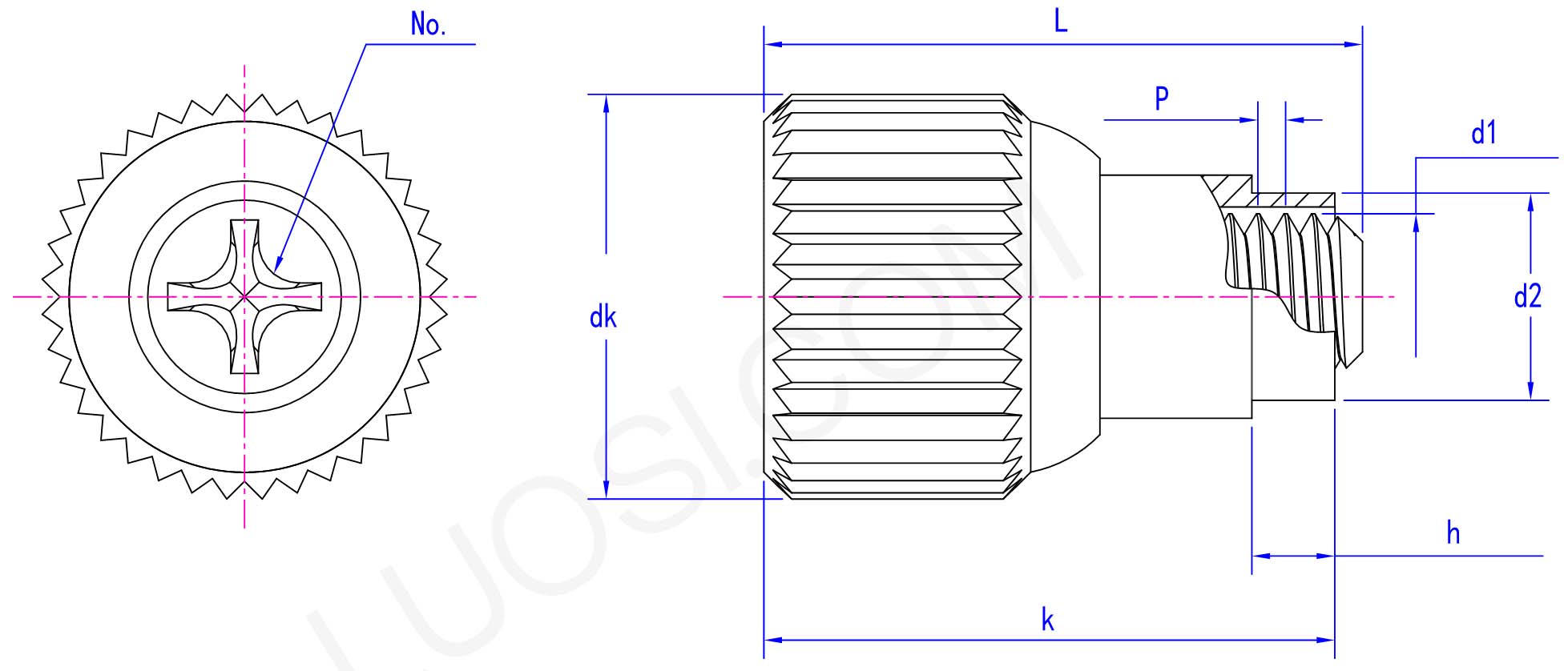

Parameter

You can get knurled head spring screws in standard metric and imperial sizes. The main measurements you need to know are:

Thread size (like M3 up to M10) and pitch

Total screw length

Head shape (usually pan or hex)

Size of the knurled bit (diameter and length)

The spring washer's dimensions (outer and inner diameter, thickness)

Product parameters

| Mon | 440 | 632 | 832 | 032 | 0420 |

| P | 40 | 32 | 32 | 32 | 20 |

| d1 | #4 | #6 | #8 | #10 | 1/4 |

| dk max | 0.432 | 0.462 | 0.522 | 0.522 | 0.589 |

| dk min | 0.404 | 0.443 | 0.502 | 0.502 | 0.569 |

| h max | 0.043 | 0.075 | 0.075 | 0.075 | 0.075 |

| h min | 0.035 | 0.067 | 0.067 | 0.067 | 0.067 |

| k | 0.445 | 0.602 | 0.614 | 0.614 | 0.76 |

| No. | 1 | 2 | 2 | 2 | 3 |

| d2 max | 0.186 | 0.212 | 0.265 | 0.265 | 0.322 |