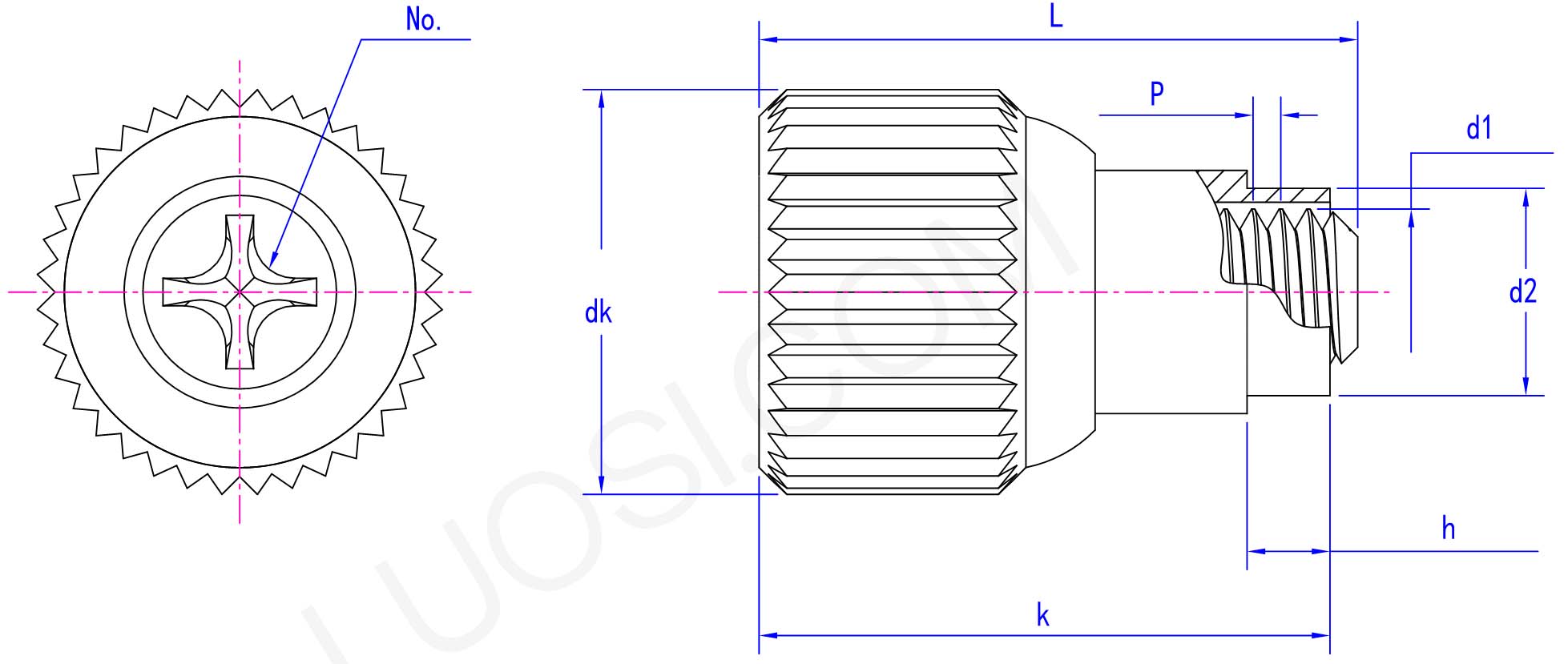

Knurled Head Spring Screw

Send Inquiry

Knurled head spring screws are usually made from high-carbon steel or tough stainless steel like SUS 304 or 316. That base material gives them good strength and the ability to resist fatigue. The knurling on the shank actually hardens the surface a bit, which helps it grip better and last longer.

Proudct parameters

| Mon | M3 | M3.5 | M4 | M5 | M6 |

| P | 0.5 | 0.6 | 0.7 | 0.8 | 1 |

| dk max | 10.75 | 11.75 | 13.25 | 13.25 | 14.95 |

| dk min | 10.25 | 11.25 | 12.75 | 12.75 | 14.45 |

| k | 11.3 | 15.3 | 15.6 | 15.6 | 19.3 |

| h max | 1.1 | 1.9 | 1.9 | 1.9 | 1.9 |

| d min | 0.9 | 1.7 | 1.7 | 1.7 | 1.7 |

| d1 | M3 | M3.5 | M4 | M5 | M6 |

| No. | 1 | 2 | 2 | 2 | 3 |

| d2 max | 4.73 | 5.38 | 6.73 | 6.73 | 8.17 |

Parameter Table

The spring washer part is designed and heat-treated to keep a steady elastic force. It won’t stay deformed even when it’s under the loads it’s meant to handle. All these materials work together so the screws hold up well under constant tension and repeated stress.

Knurled head spring screws really work well if vibrations, bumps, or heat changes would make normal screws work loose. Think places like:Cars(Holding brackets, sensors, or trim pieces);Factory machines(Keeping panels, guards, or motors attached);Electronics boxes;Aircraft parts;Outdoor equipment.

Materials And Thicknesses

Knurled head spring screws are mainly made for bendy metals such as aluminum, mild steel, copper, and brass. The usual sheet thicknesses they work with are between 0.5mm and 3.0mm per sheet,this depends on the screw size and how hard the material is. The knurled part pushes the material aside to create a lock. Just make sure to check the technical specs for the exact combinations you’re using.