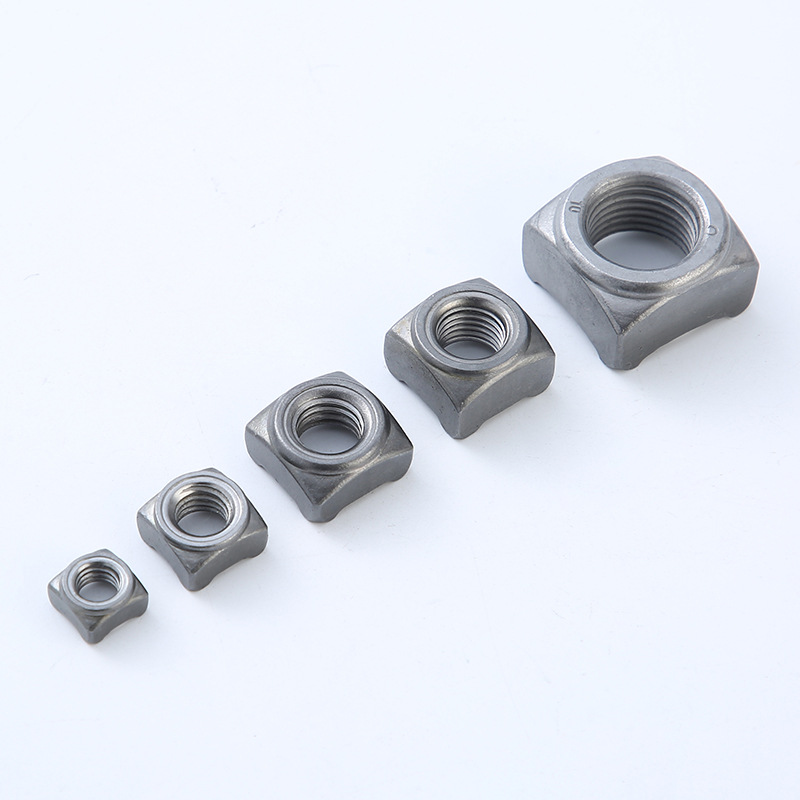

Inch Square Weld Nuts

Send Inquiry

Besides electroplating, Inch Square Weld Nuts often get phosphate coatings—like zinc or manganese phosphate. This treatment helps them resist rust, makes paint stick better if the assembly gets painted, and even adds a bit of lubrication.

For stainless steel Square Weld Nuts, passivation is the usual surface treatment. It removes free iron particles and strengthens the natural chromium oxide layer, so they resist rust as well as possible. These treatments make sure the nuts last longer and work well in whatever environment they’re used in.

Product Details

Inch Square Weld Nuts are used a lot in sheet metal work across many industries. They’re used a lot in car manufacturing—for body panels, brackets, and interior parts. Appliance makers use them to put together cabinets, frames, and internal components.

Electrical enclosures, HVAC ducts, furniture frames, and agricultural equipment all use these nuts too. They provide threaded points that are solid and easy to reach, especially in places where putting a bolt all the way through isn’t easy or wanted.

FAQ

Q: Are your Inch Square Weld Nuts compliant with international standards like ISO 21670 or DIN 928?

A:Yeah, our standard Inch Square Weld Nuts meet the relevant international standards—mainly DIN 928 for metric threads. We can manufacture square weld nuts to ISO 21670 or to your specific drawing requirements. If you need them, we can provide Conformity Certificates (CoC) or material test reports for the nuts to show they meet the requirements.

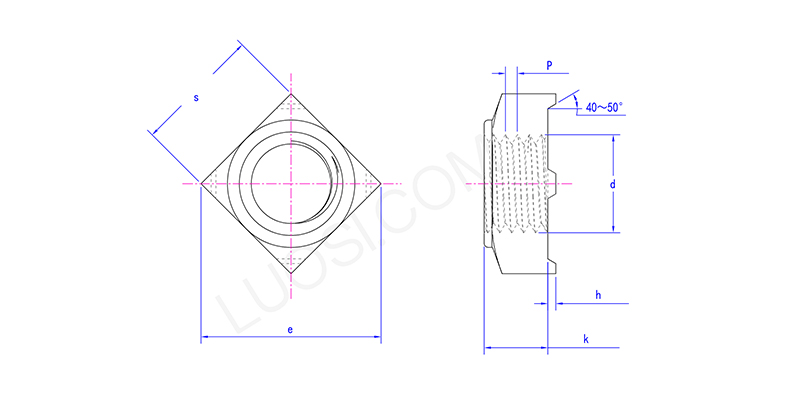

Product Parameters

| Mon | M4 | M5 | M6 | M8 | M10 | M12 |

| P | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

| e min | 9 | 12 | 13 | 18 | 22 | 25 |

| h max | 0.7 | 0.9 | 0.9 | 1.1 | 1.3 | 1.5 |

| h min | 0.5 | 0.7 | 0.7 | 0.9 | 1.1 | 1.3 |

| k max | 3.5 | 4.2 | 5 | 6.5 | 8 | 9.5 |

| k min | 3.2 | 3.9 | 4.7 | 6.14 | 7.64 | 9.14 |

| s max | 7 | 9 | 10 | 14 | 17 | 19 |

| s min | 6.64 | 8.64 | 9.64 | 13.57 | 16.57 | 18.48 |