Inch Big Square Weld Nuts

Send Inquiry

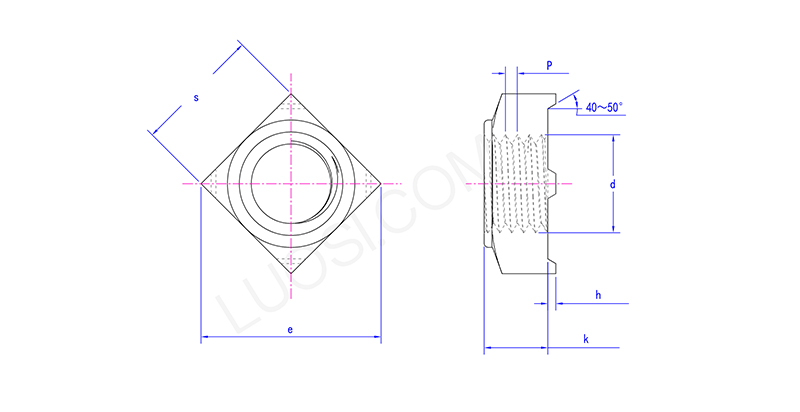

Inch Big Square Weld Nuts follow different international standards like ISO 10511, DIN 928, or ANSI/MS specs. This makes sure their sizes (like across flats, height, projection height/type) and thread sizes (metric or imperial) stay consistent. Standard sizes usually go from M3/M4 up to M12, or #6 up to 1/2".

But manufacturers often make custom Square Weld Nuts too. These can have special sizes, different projection styles, unique thread types (like fine or left-hand), or bigger bases. They’re made to fit specific load needs or unique assembly designs.

Product Details

Getting the dimensions right is really important for Inch Big Square Weld Nuts. Main specs you need to note are the width across the flats (A/F), total height (H), thread size and pitch (like M6x1.0), the pilot hole size needed in the sheet metal, and most importantly, the projection height and type—whether they’re separate nubs or a full collar.

The projection design directly affects how well they weld and how strong they are. Knowing these dimensions makes sure the nuts fit the job, weld properly, and have enough thread engagement and strength.

| Mon | 7/16 |

| P | 14 |

| e min | 0.975 |

| h max | 0.059 |

| h min | 0.051 |

| k max | 0.351 |

| k min | 0.337 |

| s max | 0.741 |

| s min | 0.721 |

FAQ

Q:What is the typical pull-out and torque strength performance for your Inch Big Square Weld Nuts after welding?

A: The pull-out and torque strength of Inch Big Square Weld Nuts really depend on the base metal—how thick it is, its grade, the welding settings, and the nut’s material and grade. If carbon steel square weld nuts are welded correctly, their tensile strength usually matches the nut’s grade. We provide suggested welding settings and basic performance info sheets for our square weld nuts to make sure the joint holds up well.