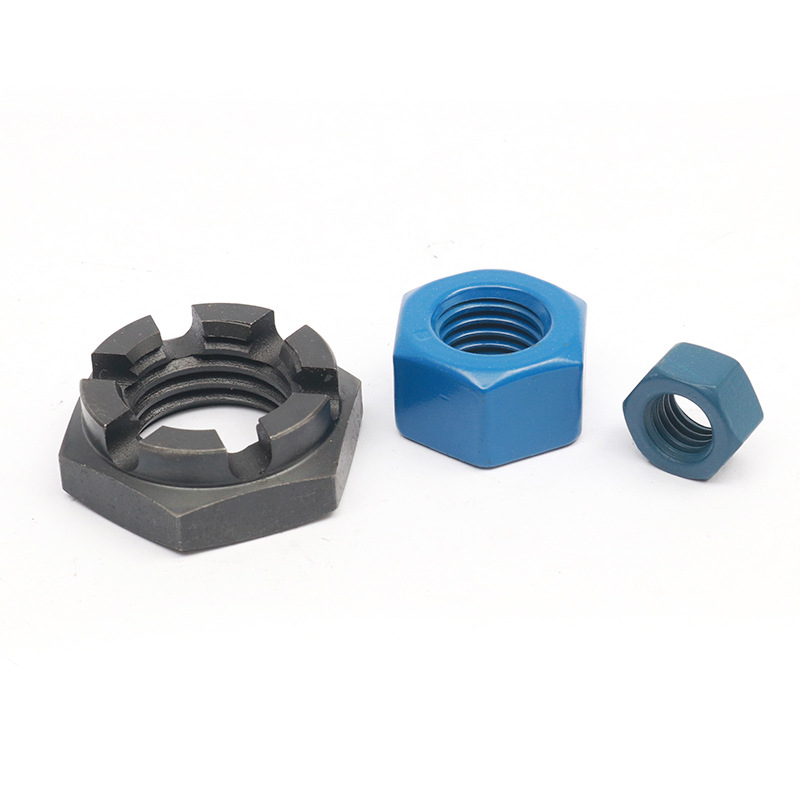

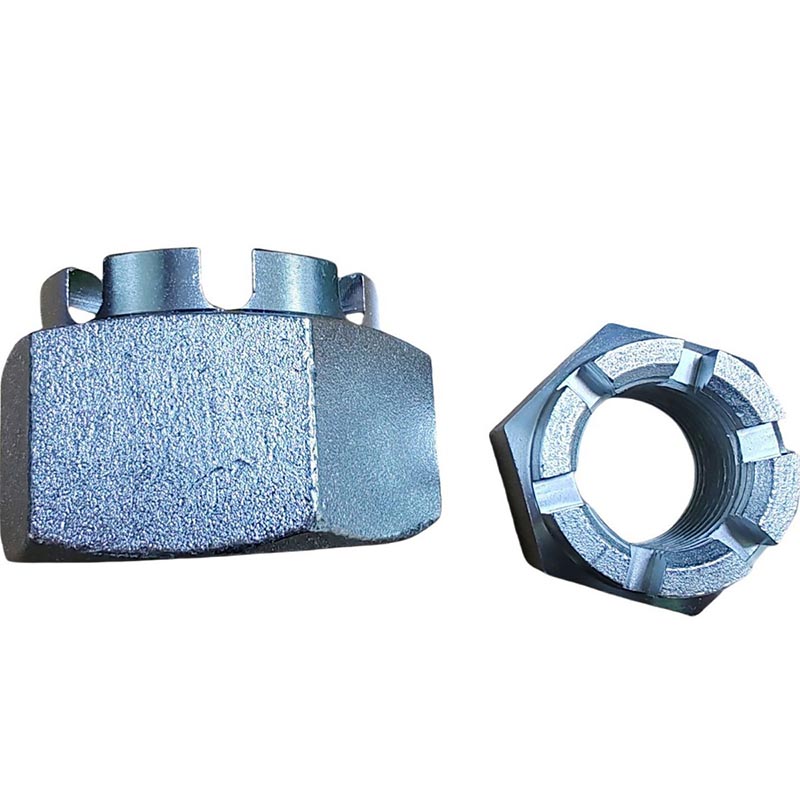

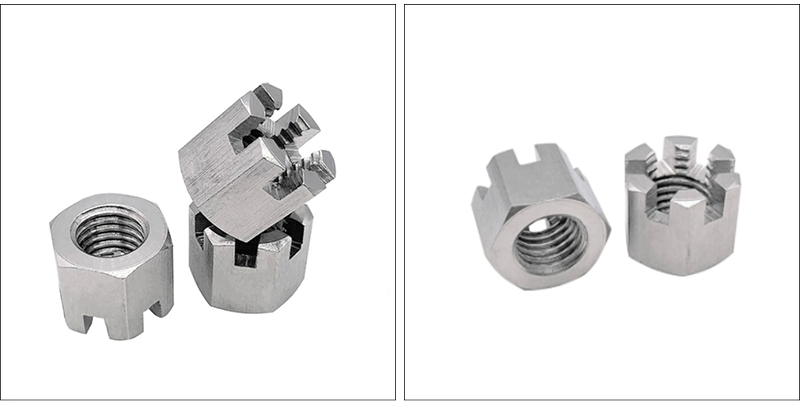

Hexagon Slotted and Castle Nuts Style 2

Send Inquiry

Hexagon slotted and castle nuts style 2 are widely used in automobile assembly, railway equipment and agricultural machinery. For example, tractor axle fixing and bridge bolt anti-loosening can be combined with pins to achieve double insurance. Xiaoguo® supports M6-M24 specification customization to meet the impact resistance requirements of heavy equipment.

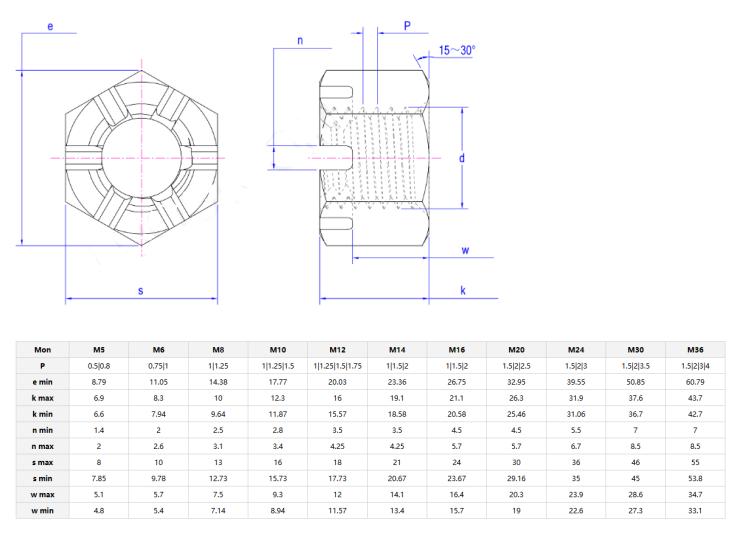

Product details and parameters

The slot top design of hexagon slotted and castle nuts style 2 can lock the cotter pin and lock it securely without worrying about vibration and loosening. For example, plowshares and tractor accessories on agricultural machinery are particularly stable when fixed with this nut; large outdoor equipment such as cranes and elevators also need the assistance of hexagon slotted and castle nuts style 2 for safety.

Xiaoguo®'s hexagon slotted and castle nuts style 2 is RoHS compliant and offers environmentally friendly plating options such as chrome-free passivation.

Market Distribution

|

Market |

Revenue(Previous Year) |

Total Revenue (%) |

|

North America |

Confidential |

20 |

|

South America |

Confidential |

9 |

|

Eastern Europe |

Confidential |

21 |

|

Southeast Asia |

Confidential |

5 |

|

Mid East |

Confidential |

3 |

|

Eastern Asia |

Confidential |

10 |

|

Western Europe |

Confidential |

16 |

|

South Asia |

Confidential |

6 |

|

Domestic Market |

Confidential |

5 |

FAQ

Zinc vs stainless for hexagon slotted and castle nuts style 2?

Depends on the application.

Cost:Zinc-plated steel is cheaper for budget projects.

Corrosion resistance:Stainless steel (with chromium) outperforms in harsh environments.

Strength:Stainless steel has higher strength and durability.

Galvanic corrosion risk:Combining zinc-plated and stainless steel parts can accelerate corrosion.