Industry Standard Spring Washers

Send Inquiry

Industry Standard Spring Washers help keep HVAC duct joints securely fastened. They’re thin—around 0.8 to 1.2mm thick—and made from zinc-plated steel, which looks silver and helps them handle moist air better. They fit common duct bolts between 10 and 14mm.

We will put these gaskets into cardboard boxes with moisture-proof function, and the boxes are filled with foam materials - this can prevent them from deforming or rusting. We will test them to ensure that they can remain in good condition even in a humid environment, and we will also check if their sizes are accurate. These gaskets also comply with the AHRI standards for HVAC equipment. Before shipment, we will inspect each batch of products to ensure that they are sealed properly as they should be.

Quality Assurance

The aerospace Industry Standard Spring Washers are used to secure the components of aircraft engines, making them firmly fastened. Made from a strong, high-temperature-resistant titanium alloy with a silver finish, these washers are well-made and available in a wide range of sizes, from 4mm to 10mm.

We pack these washers in sealed boxes that can control temperature for transportation, and each batch of goods has a tracking record. Thus, they can be safely delivered to your hands. We will test them to check for potential defects and also test their performance when the temperature reaches 500 degrees Celsius. Our washing machines meet the stringent AS9100 aerospace quality standards for added assurance. Each unit is uniquely serialized, allowing you to easily trace its origin for inspection or traceability purposes.

FAQ

Q: Can you provide Industry Standard Spring Washers with specific hardness levels for heavy-duty applications?

A: No problem, we can make spring washers that meet industry standards. If they need to support heavy weights, we can even adjust the hardness (for example, to HRC 40-50) to ensure they have sufficient elasticity and remain stable even when pressed against heavy objects.

| Mon |

Φ6 |

Φ8 |

Φ10 |

Φ12 |

Φ14 |

Φ16 |

Φ18 |

Φ20 |

Φ22 |

Φ24 |

Φ27 |

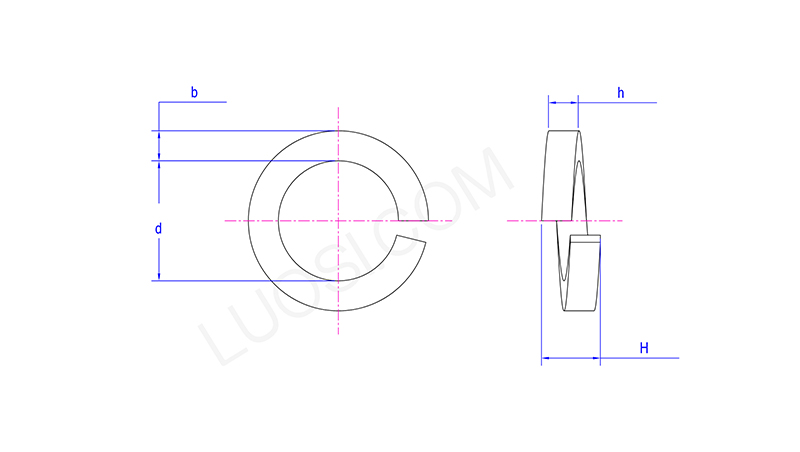

| d min | 6.1 | 8.1 | 10.2 | 12.2 | 14.2 | 16.2 | 18.2 | 20.2 | 22.5 | 24.5 | 27.5 |

| d max | 6.68 | 8.68 | 10.9 | 12.9 | 14.9 | 16.9 | 19.04 | 21.04 | 23.34 | 25.5 | 28.5 |

| b min | 1.5 | 2 | 2.45 | 2.95 | 3.4 | 3.9 | 4.3 | 4.8 | 5.3 | 5.8 | 6.5 |

| b max | 1.7 | 2.2 | 2.75 | 3.25 | 3.8 | 4.3 | 4.7 | 5.2 | 5.7 | 6.2 | 7.1 |

| h min | 1.5 | 2 | 2.45 | 2.95 | 3.4 | 3.9 | 4.3 | 4.8 | 5.3 | 5.8 | 6.5 |

| h max | 1.7 | 2.2 | 2.75 | 3.25 | 3.8 | 4.3 | 4.7 | 5.2 | 5.7 | 6.2 | 7.1 |

| H min | 3.2 | 4.2 | 5.2 | 6.2 | 7.2 | 8.2 | 9 | 10 | 11 | 12 | 13.6 |

| H max | 4 | 5.25 | 6.5 | 7.75 | 9 | 10.25 | 11.25 | 12.5 | 13.75 | 15 | 17 |