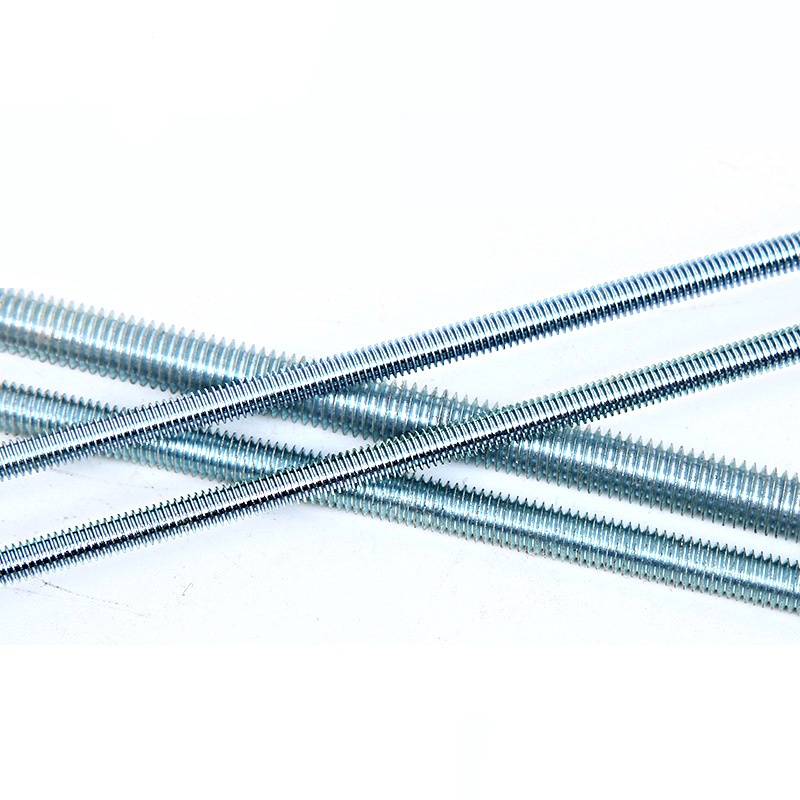

Full Threaded Stud Bolts

Send Inquiry

The railway system uses Full Threaded Stud Bolts to connect the rails and assemble locomotives. These Full-Threaded Stud bolts need to be able to withstand vibration and heavy loads. They are made of heat-treated steel, have a black oxide layer on the surface, and have a locking thread function. We can schedule the delivery time according to the maintenance plan, including weekend delivery to avoid disrupting normal operations. The freight is priced by carriage, with a discount when fully loaded. The bolts are installed in steel frames suitable for standard railway containers to ensure safety during transportation. We conduct fatigue resistance tests on them, up to 10^6 cycles, and they comply with the EN 14399 standard, which is a common standard adopted by the European railway industry.

Product Details

In medical equipment, such as MRI machines and surgical tools, Full Threaded Stud Bolts are used. These Full-Threaded Stud bolts must be non-magnetic and extremely precise. They are usually made of brass or titanium, have smooth threads, and do not irritate tissues.

We transport them in sterile packaging and control the temperature as necessary. Most orders will be delivered within 2 to 3 days. The shipping cost includes the cost of biological hazard disposal. For small quantities or urgent shipments, the price may be adjusted.

These bolts are placed in sealed and sterilizable bags and placed in a sturdy plastic box to keep them clean. Each bolt is inspected under a microscope to look for any defects. We also hold ISO 13485 certification – a core demonstration of quality compliance for medical devices – demonstrating our strict adherence to product quality standards.

Customized Services

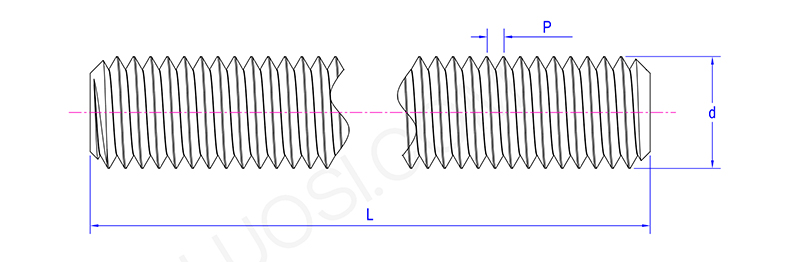

We are skilled at manufacturing custom products. If you need Full Threaded Stud Bolts with lengths, diameters, or pitch spacings that differ from standard specifications, we can precisely produce them according to your drawings. Our engineering team will collaborate with you to ensure that these custom fasteners can meet your specific mechanical performance and dimensional requirements during use.

| Mon | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 |

| P | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 |