Forged Eye Bolt

Send Inquiry

Forged eye bolt are strong fasteners used for lifting, rigging, and anchoring. They have a round "eye" loop at one end and a threaded shaft at the other. These let you attach cables, ropes, or chains securely. They’re made to handle both moving and stationary loads. You’ll see them a lot in construction, marine work, and logistics.

There are different types, like shoulder bolt, machinery bolt, and screw eyes. Each type works for different load sizes and environments. Their design is tough and reliable, which makes them important for keeping things safe and working well in industrial settings.

Product details:

Forged eye bolt come in thread sizes ranging from M6 all the way up to M48, and they’re rated for loads between 50kg to over 20 tons. If you’re using shoulder-type ones, just remember – you gotta screw them all the way in to hit their max weight rating. Screw eyes? Those are better for lighter jobs. Always check if they’ve got certifications like DIN, ISO, or ASTM – that’s how you know they’re legit.

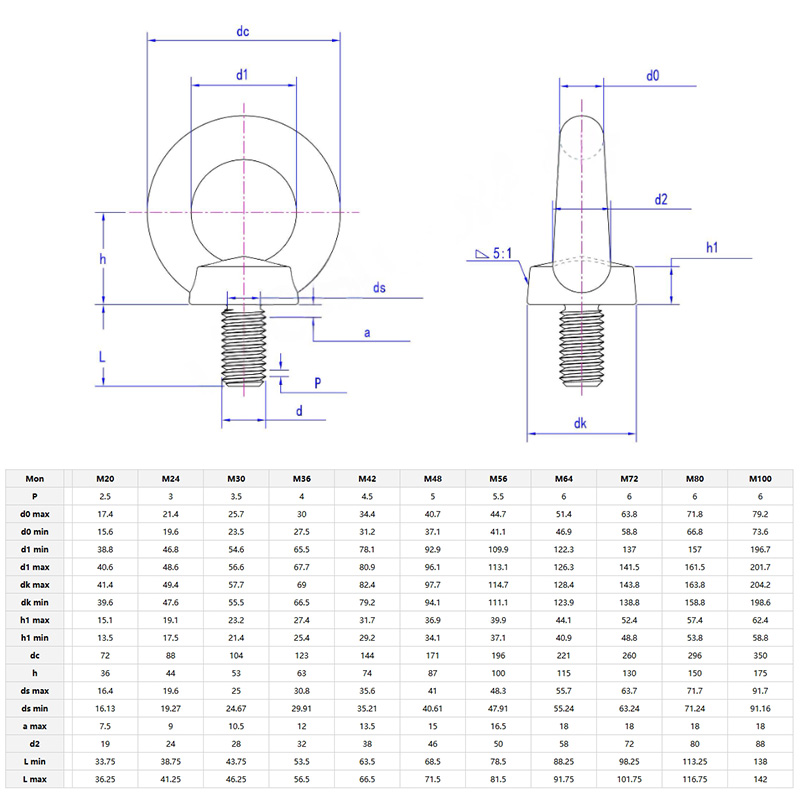

Stuff like the eye’s size, shank length, and thread spacing depends on your job, so cross-check the weight charts to avoid mismatches. Need something weird for a special project? Some suppliers will even tweak the sizes or threads for you. Just don’t skip the details when ordering.

Product parameters

FAQ

Q: What is the maximum weight capacity of your forged eye bolt, and how is it determined?

A:How much weight it can hold really comes down to three things: what it’s made from, how thick it is, and the way it’s built. Take carbon steel forged ones, for instance – they’re tougher than stamped or bent versions and can handle anywhere from 0.25 tons up to 11 tons. The Working Load Limit (WLL) – that’s the max safe weight they can handle – is figured out using rules like ASME B30.26 or DIN 580. These rules build in a safety cushion, usually a 4:1 or 5:1 ratio, so they’re way stronger than the number suggests. Basically, if it’s rated for 1 ton, it’s actually built to handle 4 or 5 tons before anything goes sideways.