Floating spring screws

Send Inquiry

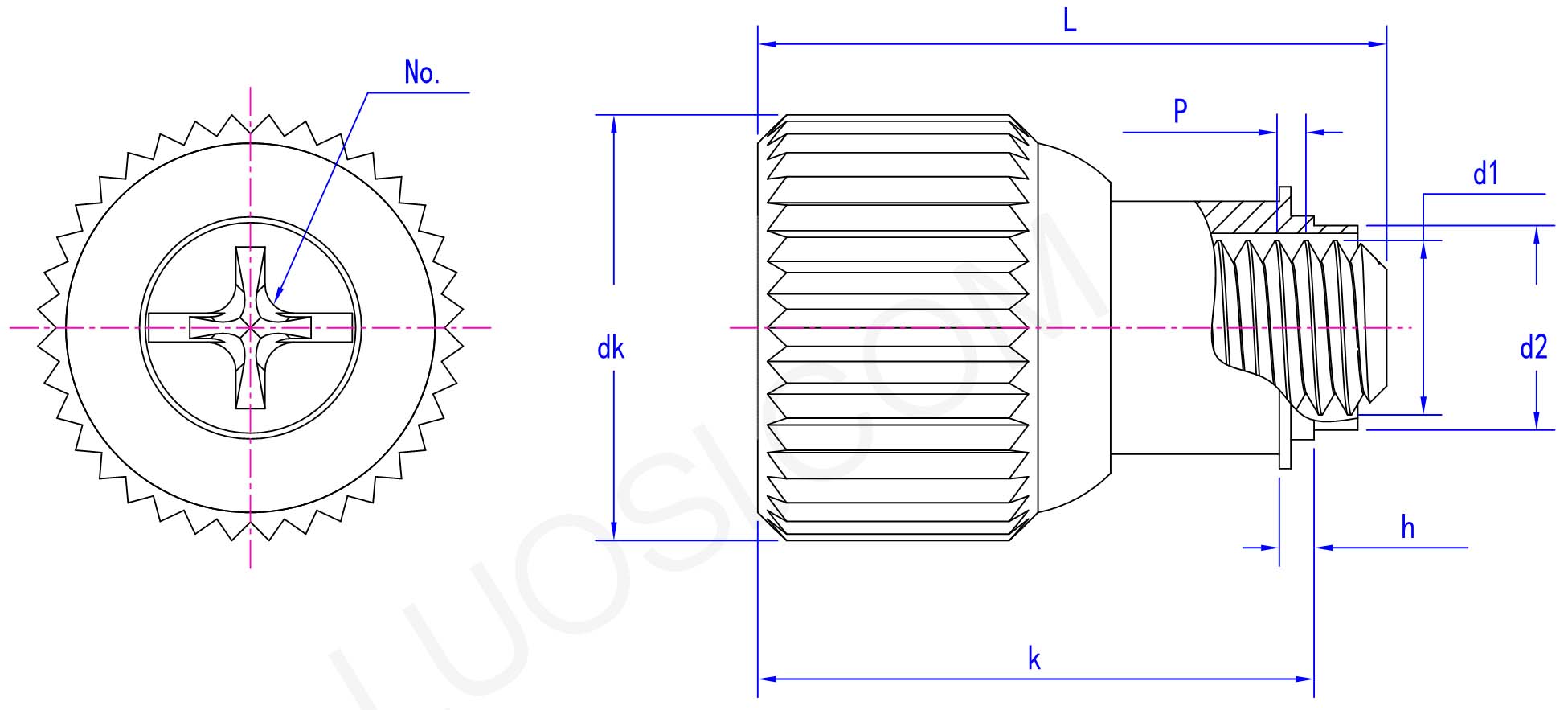

Floating spring screws do three important things all in one: they thread like normal screws, the spring washer stops vibrations, and the knurled part keeps them from spinning. This design cuts down the chance of them coming loose on their own, plus you don’t need a separate lock washer so there are fewer parts. That makes assembly faster and the joint more reliable.

These screws are tough and work great in hard-to-reach spots, high-vibration areas, or any place where a solid hold is a must.

Product parameters

| Mon | M3 | M3.5 | M4 | M5 |

| P | 0.5 | 0.6 | 0.7 | 0.8 |

| d1 | M3 | M3.5 | M4 | M5 |

| d2 min | 4.67 | 5.32 | 6.67 | 6.67 |

| d2 max | 4.79 | 5.44 | 6.79 | 6.79 |

| dk max | 10.75 | 11.75 | 13.25 | 13.25 |

| dk min | 10.25 | 11.25 | 12.75 | 12.75 |

| h | 0.97 | 0.97 | 0.97 | 0.97 |

| k | 11.9 | 15.4 | 16.2 | 16.2 |

| No. | 1 | 2 | 2 | 2 |

Advantages

The Floating spring screws can keep joints tight for the long haul, even in rough conditions. They solve two problems: they won’t shake loose and won’t lose grip from vibrations or material settling. This means less downtime, fewer warranty headaches, and safer operation.

They might cost a little more upfront than basic screws with separate washers. But because they last longer without issues, install quicker, and need less fuss over time, they actually save you money. Makes them a solid option for reliable fastening.

How consistent is the joint strength achieved?

When you install Floating spring screws right,sticking to the recommended force and die specs,the joint strength ends up really consistent. The knurled pattern makes sure the material gets pushed aside evenly, forming a solid lock every time. The spring part also gives a clamping force that’s predictable and the same each time.

With strict process control, you can count on the pull-out and shear strength being reliable, which is key for keeping structural integrity.