Eye Bolt

Send Inquiry

To fight rust and wear out, eye bolt get special coatings or treatments. Carbon steel ones often get hot-dip galvanizing—they’re dipped in hot zinc to add a protective layer, which works great for outdoor or damp environments. Electroplating forms a thin protective layer, which is usually sufficient for indoor use. Stainless steel inherently has excellent rust prevention properties. However, additional processing steps are also carried out to further enhance its rust resistance. The powder coating acts as a protective layer, not only providing a more attractive appearance but also protecting against sunlight exposure. These treatment methods help them to be used for a longer period of time and remain sturdy even under harsh conditions.

Product details:

Eye bolt offer a really solid mix of strength, flexibility, and safety. Their design works for straight lifting or angled loads, and with different materials and coatings, they fit all kinds of situations. Whether you’re doing a small DIY project or a big industrial job, they’re reliable for anchoring stuff. Certifications mean they’re good quality, and having different sizes means you can get what you need without overspending. Because they’re well-made and focus on keeping users safe,bolts are a top pick for pros everywhere—they balance being useful and long-lasting pretty well.

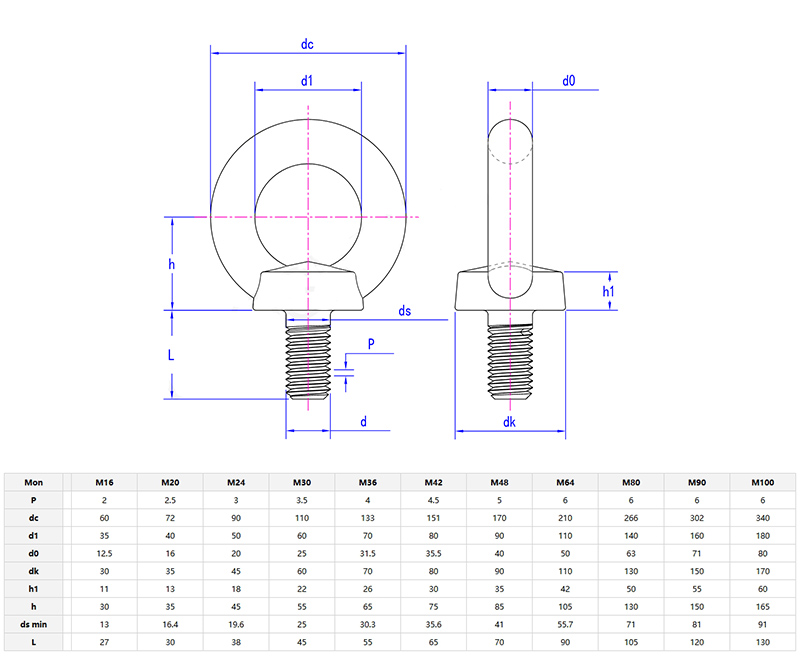

Product parameters

FAQ

Q: Do your eye bolts comply with international safety certifications?

A: Yep, our product meet CE, OSHA, and ISO 17025 standards, and we can provide test certificates if you ask for them. We do thorough quality checks, including load testing, checking the material makeup, and making sure the sizes are right. We add custom labels (like WLL and batch numbers) so you can track them easily.

For the EU market, our eye bolts meet the rules under Machinery Directive 2006/42/EC, and we have RoHS-compliant coatings for projects with environmental regulations. Work with us for certified bolts that are ready for audits and meet the specific compliance needs in your region.