Double Ends Anchor Bolt

Send Inquiry

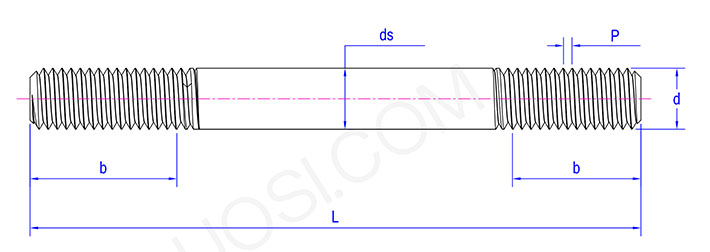

The double ends anchor bolt is made of steel. The middle part is a smooth rod body with threads at both ends. In environments where high strength is required or where rust is prone to occur, high-strength carbon steel or stainless steel materials will be used.

Features

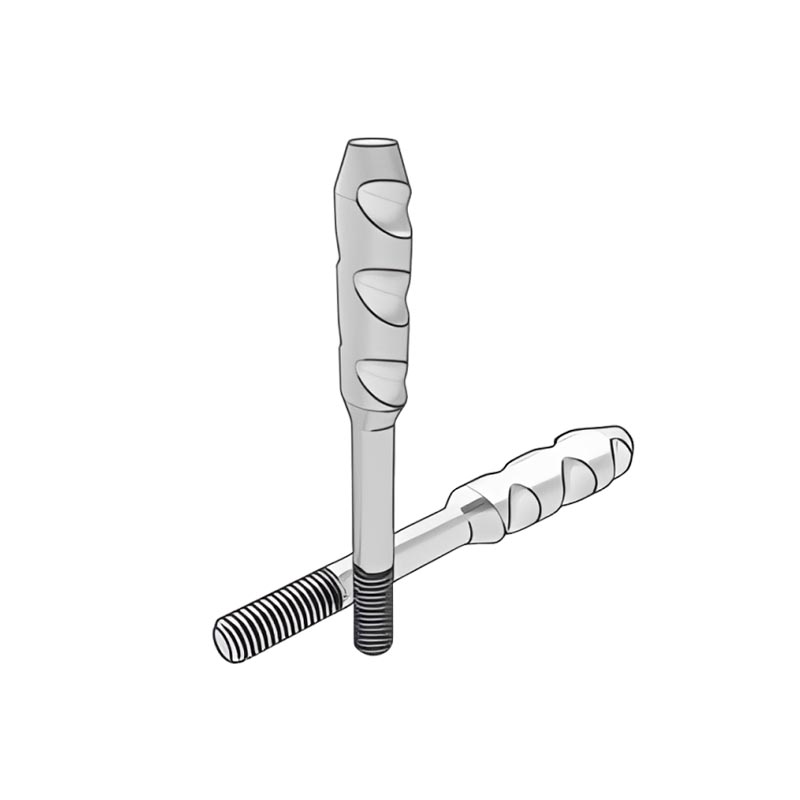

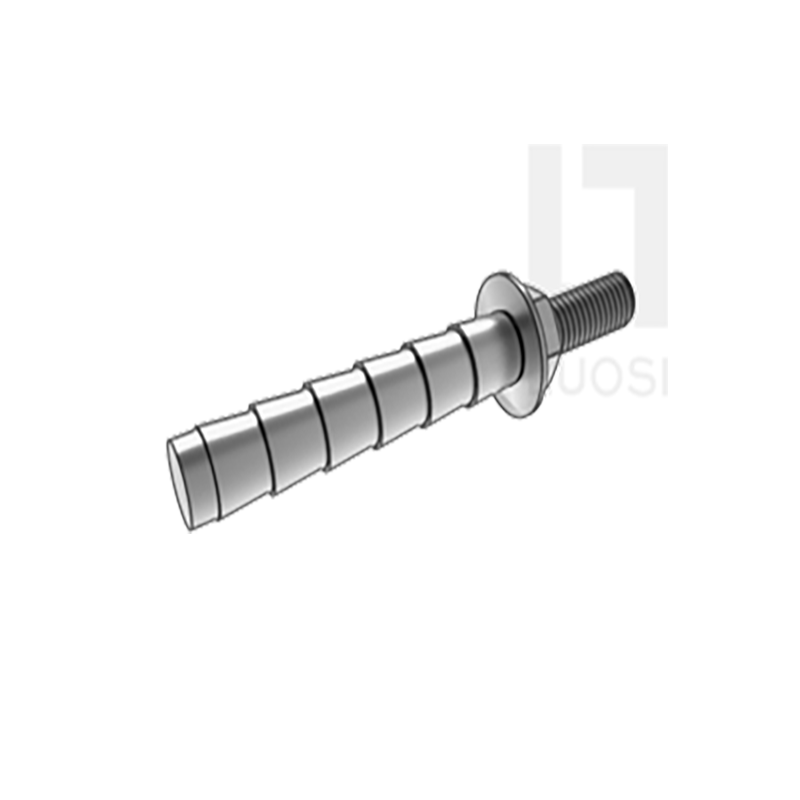

Double ends anchor bolts can be screwed into concrete and equipment. One end is embedded in the wet concrete like a standard anchor bolt; The other end extends out with threads and is used to fix the machine. There is no need to drill holes separately in the workshop to install bolts and anchor bolts.

Double-sided threaded bolts can withstand severe vibrations. You need to embed the serrated end into the concrete and fix the exposed threads with double nuts to adapt to the mechanical equipment. Compared with the single-head anchor bolts used in generator sets, its seismic performance is stronger.

Double end anchor bolts can withstand earthquakes. The built-in hook can resist floating. Exposed threads can be used to support steel frames with crossbars. This is crucial for earthquake-prone areas that require fixed equipment. They are suitable for temporary installation. Embed it into the concrete block for activity construction; After that, remove the structure and reuse the bolts. It is more economical than welding temporary supports.

Product parameters

| Mon | M20 | M24 | M27 | M30 | M36 | M42 | M48 | M56 | M64 | M72 | M80 |

| P | 2.5 | 3 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 |

| b max | 80 | 96 | 108 | 120 | 144 | 168 | 192 | 224 | 256 | 288 | 320 |

| b min | 60 | 72 | 81 | 90 | 108 | 126 | 144 | 158 | 192 | 216 | 240 |

| ds max | 20.84 | 24.84 | 27.84 | 30.84 | 37 | 43 | 49 | 57.2 | 65.2 | 73.2 | 81.2 |

| ds min | 19.16 | 23.16 | 26.16 | 29.16 | 35 | 41 | 47 | 54.8 | 62.8 | 70.8 | 78.8 |

Advantage

The characteristics of double ends anchor bolts are simple structure, no complex design, low manufacturing cost, and workers can use them easily. When installing, first screw one end of the bolt into the threaded hole of the foundation or pre-embed it in the foundation. After the equipment or component is in place, pass the other end through the installation hole and then screw on the nut and tighten it. No special tools or complex operation procedures are required, which can save installation time and labor costs.