Cotter Pins

Send Inquiry

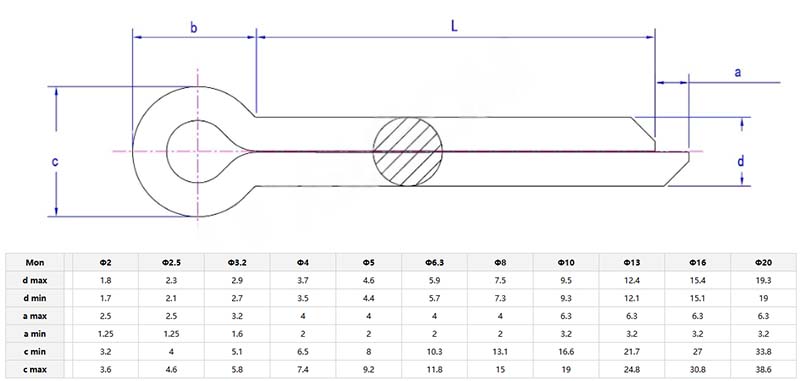

Cotter pins, also called split pins, are simple yet key fastener. It’s just a U-shaped piece of metal wire with two prongs. You push it through a hole in a bolt, nut, or threaded part to keep things from coming loose. After you put it in, you bend those two prongs outward to lock everything in place.

Pins are easy to use and perform well. They are suitable for cars, bicycles, machines and any equipment with moving parts. They can lock parts, resist vibrations and are not easy to loosen, making them ideal for equipment that is often under pressure. Xiaoguo® Factory offers a variety of sizes and materials (such as steel or stainless steel), so you can choose the right model according to the ring you use and your needs.

Feature

Cotter pins are good because it’s cheap, tough, and works for a lot of things. Unlike fancy fasteners, you don’t need special tools to put it in,just regular pliers to bend those split ends and hold it in place. The way it’s designed means parts stay locked even when there’s a ton of vibration or heavy loads. Plus, you can reuse them a lot of the time, which saves money on maintenance. And they’re light, so they don’t add much weight or bulk to machines. Whether you’re using them on farm equipment, bikes, or big heavy machines, cotter pin keep things secure. That’s why engineers and mechanics everywhere like them.

Materials

Q: What materials are commonly used in manufacturing cotter pins, and which offers the best corrosion resistance?

A: These pins are mostly made of carbon steel, stainless steel or brass. Stainless steel is not prone to rust, so it is suitable for damp places. Carbon steel is inexpensive and can undergo surface treatment to prevent rusting. If you used them in harsh conditions, then use stainless steel.