Corrugated Spring Washer

Send Inquiry

Corrugated spring washer use common materials like carbon steel (grades 8.8 or 12.9), stainless steel (A2 or A4 types), and beryllium copper for situations where sparks could be a problem (like flammable environments). For important applications that need high performance, they might use grades like ASTM A194 or SAE J484.

Some get heat-treated (quenched and tempered) to make corrugated spring washer harder and more springy, while softer (annealed) versions work for low-stress jobs. Many materials meet certifications like RoHS or REACH to follow environmental and safety rules. For special uses, they might use composite materials or plastic coatings in niche industries.

Extend service life

To make corrugated spring washer last longer, it’s a good idea to check them regularly for any bending, rust, or wear. Don’t tighten them too much,if you compress them too hard, they might stay flat and lose their springiness for good. In places where there’s a lot of corrosion, the gasket status should be observed at all times and the coated gasket should be replaced in a timely manner as required.

You usually don’t need to lubricate the corrugated spring washer unless the coating specifically needs it,some coatings already have self-lubricating stuff. Keep them stored in dry areas to stop rust before you install them. When using them, make sure the bolts and nuts they’re paired with are compatible to avoid corrosion between different metals, especially if the metals are different from the washer’s material.

Bear load

Q: What factors decide how much load corrugated spring washer can handle?

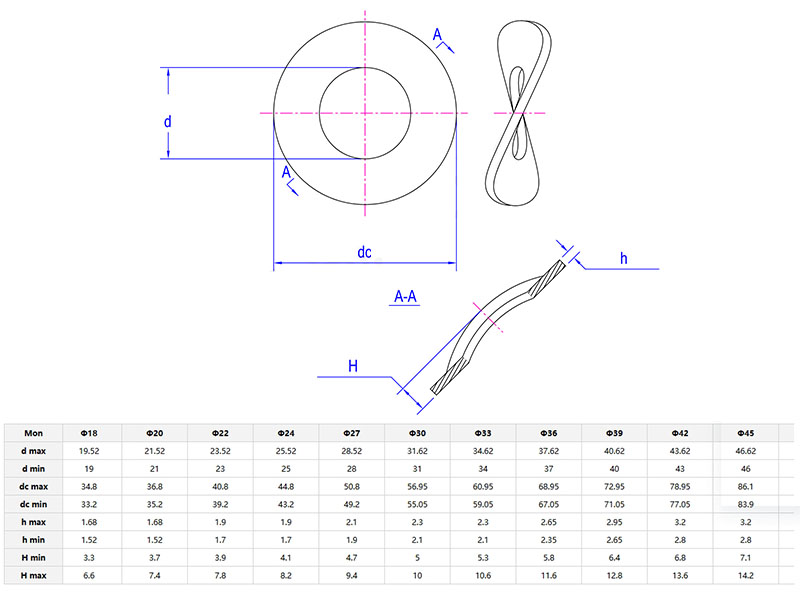

A: A corrugated spring washer’s load capacity depends on its material’s tensile strength, thickness, outer diameter, and how sharply it’s curved (curvature angle). Thicker washers with a steeper curve usually offer more spring force, but they can’t bend as much (smaller deflection range). For example, a 10mm outer diameter stainless steel washer might hold 200–500 Newtons, depending on the specs.

Engineers need to figure out how much preload force is needed and compare it to the corrugated spring washer’s “spring rate”(how much force it gives per unit of bending). If you overload it beyond its elastic limit, it’ll stay flat and stop working.Please select the appropriate product based on the load-deflection charts provided by the Xiaoguo® supplier, and do not simply speculate based on size or material.