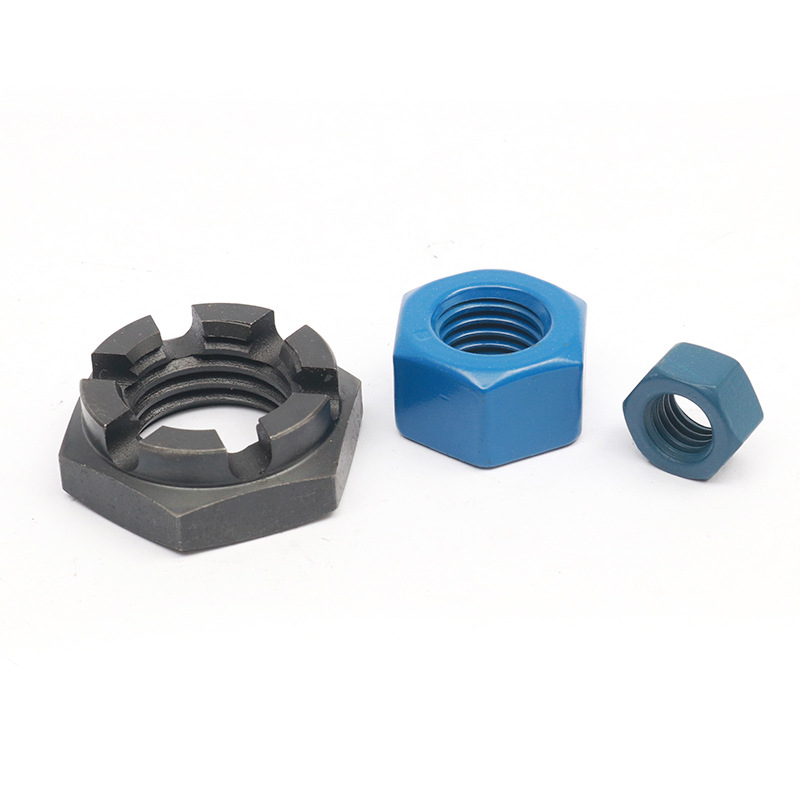

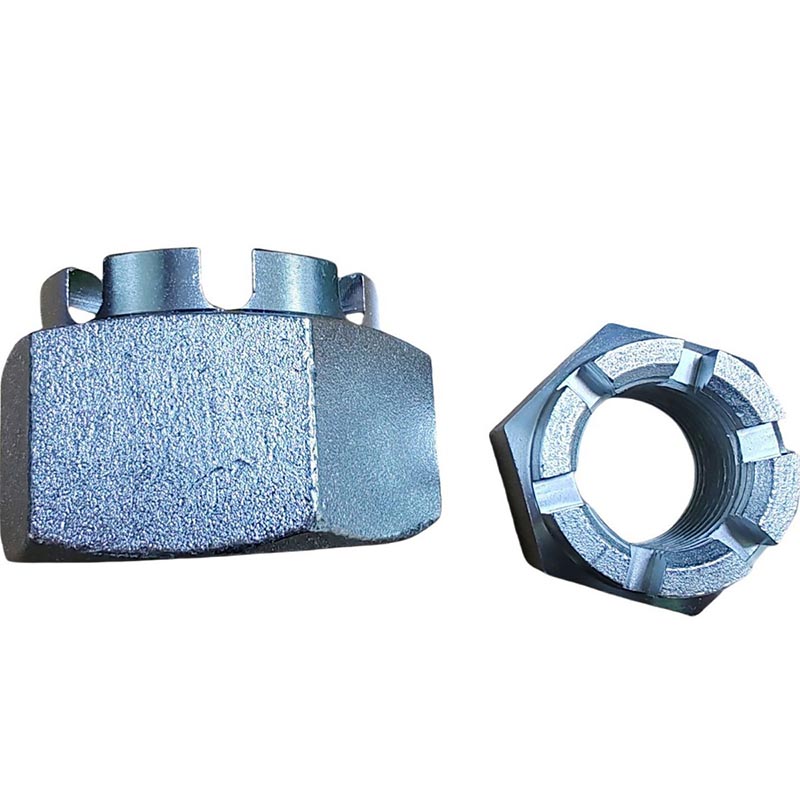

Corrosion Conquering Crown Nut With Slot

Send Inquiry

Corrosion Conquering Crown Nut With Slot are made to exact size standards so they fit right and work properly. Common ones include ISO 4161, DIN 935, and specific aerospace standards like NASM or MS. The sizes cover things like the hex width (for the wrench), thread size and pitch (like M10x1.5 or 1/2"-13), total height, crown diameter, and slot width and depth. It is crucial to select slotted crown nuts that are precisely sized to ensure a good fit with the mating component, effective tightening, and precise alignment with the hole reserved for the bolt or stud.

Excellent product quality

Choosing the material for Corrosion Conquering Crown Nut With Slot follows strict rules to make sure they work as they should. Steel nuts can meet the requirements of many mainstream standards, including ISO 898-2 (covering performance levels 6, 8, 10, and 12) and SAE J995 (covering levels 5 and 8). They also comply with standards such as ASTM A194/A563 and are suitable for most common application scenarios. Stainless steel ones use AISI 304/316 or ASTM F594. For tough aerospace jobs, they use high-performance alloys like A286 or Inconel 718. The material grade of the slotted crown nut has a direct and decisive influence on its strength index, temperature resistance and corrosion resistance.

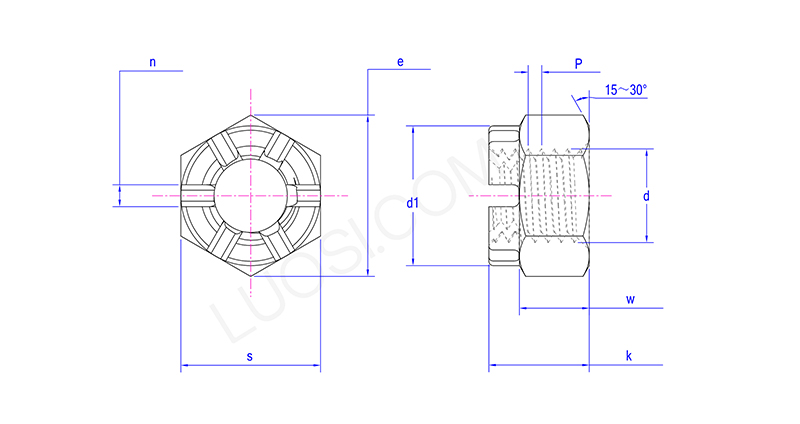

| Mon | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 |

| P | 1.5|2 |

1.5|2 |

1.5|2 |

1.5|2 |

1.5|2 |

1.5|2 |

1.5|2 |

1.5|2|3 |

| d1 max | 25 | 28 | 30 | 34 | 38 | 42 | 46 | 50 |

| d1 max | 24.16 | 27.16 | 29.16 | 33 | 37 | 41 | 45 | 49 |

| e min | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 |

| k max | 23.6 | 26.3 | 29.8 | 31.9 | 34.7 | 37.6 | 41.5 | 43.7 |

| k min | 22.76 | 25.46 | 28.96 | 30.9 | 33.7 | 36.6 | 40.5 | 42.7 |

| n max | 5.7 | 5.7 | 6.7 | 6.7 | 6.7 | 8.5 | 8.5 | 8.5 |

| n min | 4.5 | 4.5 | 5.5 | 5.5 | 5.5 | 7 | 7 | 7 |

| s max | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 |

| s min | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 |

| w max | 17.6 | 20.3 | 21.8 | 23.9 | 26.7 | 28.6 | 32.5 | 34.7 |

| w min | 16.9 | 19.46 | 20.5 | 23.06 | 25.4 | 27.76 | 30.9 | 33.7 |

Quality Certification

We make our Corrosion Conquering Crown Nut With Slot under an ISO 9001:2015 certified quality system. We follow the relevant DIN and ISO standards, like DIN 935. If you need material certificates (3.1 or 3.2), we can provide those. We also make sure they meet RoHS and REACH rules for restricted substances. If you need specific industry certifications—like for automotive or aerospace—we can talk about that based on what your project needs for the slotted crown nuts.